Fine Beautiful Tips About Should Wires Be Tinned Before Crimping

What Is A Wire System Design Talk

To Tin or Not to Tin

1. The Great Wire-Tinning Debate

Alright, let's dive into a topic that sparks more debate in electrical circles than pineapple on pizza: tinning wires before crimping. You've got your bare wire ends, a crimping tool, and that little voice in your head whispering, "Should I tin these first?" Well, I'm here to help you quiet that voice — or maybe amplify it, depending on where you stand!

At its core, tinning involves coating the exposed strands of a wire with solder. The idea is to create a solid, unified end that supposedly makes for a better connection when crimped. But does it actually live up to the hype? Or are we just adding an unnecessary step to our projects?

Think of it like this: crimping is like a really enthusiastic handshake between the wire and the connector. You want a firm, solid grip. Tinning, in theory, should solidify that handshake, preventing any wobbly fingers (or wire strands) from spoiling the deal. But sometimes, an overly enthusiastic handshake can crush the bones, right? That's where things get interesting.

So, before we get too deep into the pros and cons, remember this: the goal is a secure, reliable electrical connection. Let's explore if tinning helps or hinders that goal.

2. Understanding the Contenders

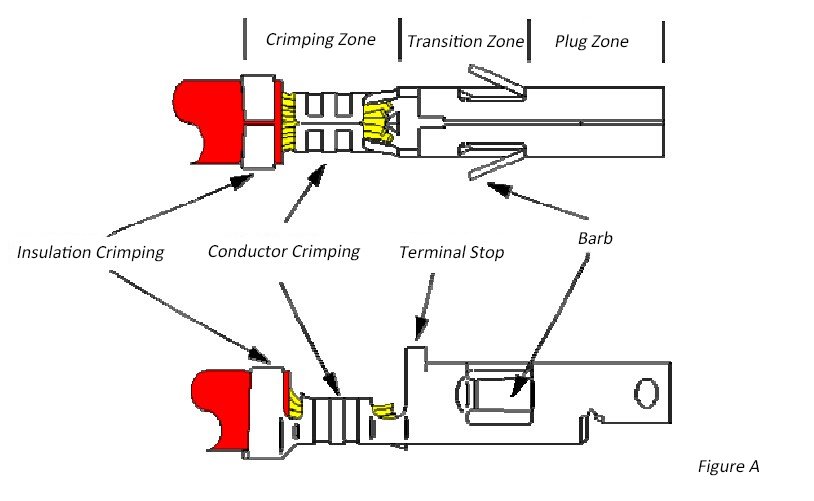

Let's quickly distinguish between crimping and soldering because that's key here. Crimping uses mechanical pressure to create a connection, forcing the connector to bite into the wire strands. Soldering, on the other hand, uses molten solder to bond the wire and connector together metallurgically. They're like cousins, related but with very different approaches.

Crimping, when done correctly with the right tools and connectors, creates a gas-tight seal that prevents corrosion and ensures a long-lasting connection. It's often preferred in applications where vibration or movement are present, as the mechanical connection is more robust than a solder joint in these situations. Think cars, boats, and even aerospace applications.

Soldering, while creating a strong initial bond, can be more susceptible to fatigue and cracking over time, especially under stress or vibration. Also, let's be honest, getting a perfect solder joint every single time takes some skill and practice. A cold solder joint is a sad thing indeed.

The question we're tackling is whether adding solder (tinning) before crimping gives you the best of both worlds, or just a confused, compromised connection. The answer, as with many things in life, isn't a simple yes or no.

The Case Against Tinning Before Crimping

3. Why Tinning Can Be a Terrible Idea

Alright, let's hear the prosecution's case against tinning before crimping. The main argument boils down to this: tinning can actually weaken the crimp connection. Whoa, hold on! How can that be?

When you tin a wire, you're essentially making the wire end solid. This means that when you crimp it, the connector can't properly deform and grip the individual strands. Instead, it's trying to crush a solid lump of solder and wire. The solder, being softer than the copper, will deform first. And here's the kicker: solder creeps over time. That means it slowly flows under pressure. This can lead to the crimp loosening, increasing resistance, and eventually causing the connection to fail. Not ideal, especially in critical applications.

Imagine trying to build a strong foundation for a house on quicksand. That's essentially what you're doing when you crimp a tinned wire. The solid end prevents the connector from properly meshing with the wire strands, leading to a less secure and less reliable connection over the long haul.

Furthermore, the tinning process itself can introduce problems. If you overheat the wire during tinning, you can damage the insulation and weaken the copper. Plus, let's face it, getting a perfectly even coating of solder every time is tricky. Uneven tinning can lead to uneven crimping, further compromising the connection.

The Case For Tinning (Sometimes...)

4. When Tinning Might Actually Be Okay

Now, before you throw your soldering iron out the window, let's consider the defense's argument. There are some situations where tinning might be acceptable, even beneficial.

One scenario is when dealing with stranded wire that frays excessively. If the strands are constantly splaying out, making it difficult to insert the wire into the connector, a light tinning can help keep them together. However, light is the key word here. You only want to use enough solder to hold the strands together, not to create a solid lump.

Another situation is when working with very fine-stranded wire. These wires can be particularly prone to fraying and can be difficult to crimp effectively. Again, a very light tinning can help to consolidate the strands and improve the connection. Emphasis on "very" — think a whisper of solder, not a shout.

Finally, in some very specific low-current, non-critical applications, tinning might be used for convenience. However, it's generally not recommended for high-current or safety-critical circuits.

Bottom line: if you do choose to tin before crimping, proceed with extreme caution. Use as little solder as possible, ensure the wire doesn't overheat, and double-check the crimp for tightness and security. And even then, be aware that you might be compromising the long-term reliability of the connection.

Analysis Of The Reasons Leading To Production Defective

Crimping Done Right

5. Mastering the Art of the Crimp

So, if tinning is often a no-no, what's the secret to a perfect crimp? It all comes down to using the right tools and techniques. Firstly, invest in a good quality crimping tool designed for the specific connectors you're using. A cheap crimper will give you cheap results — think loose connections, broken wires, and electrical headaches.

Secondly, use the correct size connector for the wire gauge. Over- or under-sizing the connector will lead to a weak or unreliable connection. Consult a wire gauge chart to determine the appropriate connector size for your wire.

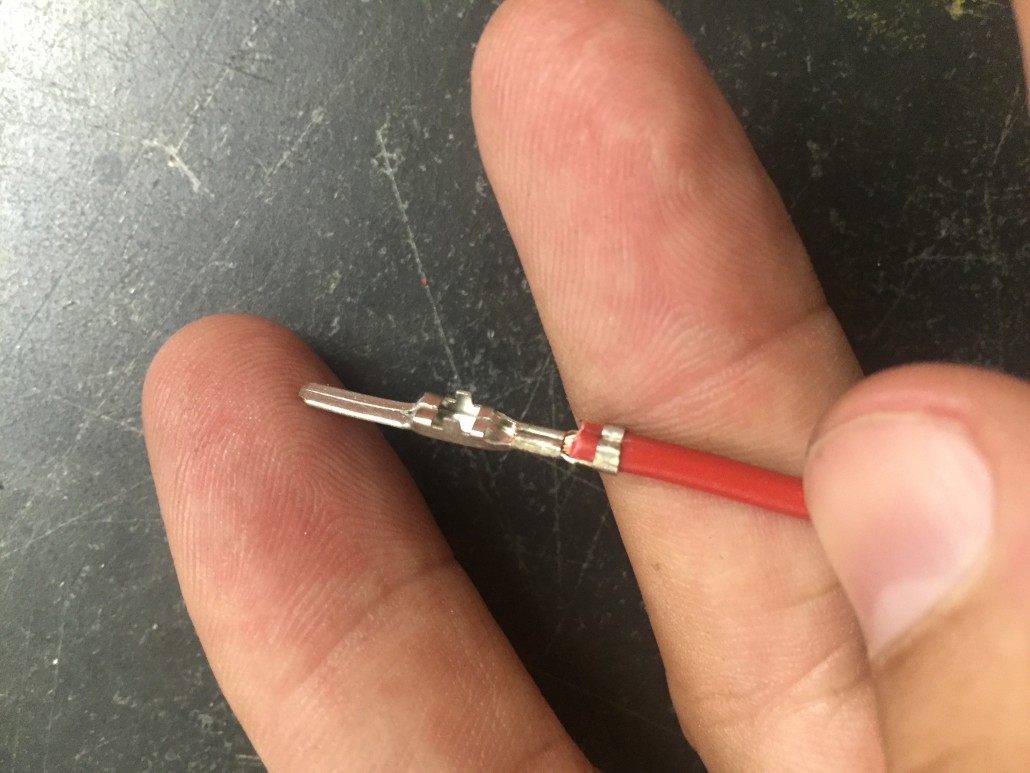

Thirdly, strip the wire to the correct length. Too much exposed wire can lead to shorts, while too little can result in a poor crimp. Most connectors will have a mark indicating the proper strip length. After stripping, give the wire a gentle twist to keep the strands together, but avoid over-twisting, which can make it difficult to insert into the connector.

Finally, insert the wire fully into the connector and crimp firmly using the appropriate setting on your crimping tool. Inspect the crimp to ensure it's secure and that the connector has properly deformed around the wire. A properly crimped connection should be strong enough to withstand a reasonable amount of pulling without coming loose.

Terminating Wires By Crimping TTI, Inc.

Frequently Asked Questions (The Burning Questions Answered!)

6. Your Crimping Conundrums, Solved

Let's address some of the common questions that pop up regarding crimping and tinning.

Q: Should I ever solder a crimped connection?A: Generally, no. A properly crimped connection shouldn't need soldering. Adding solder can introduce stress points and weaken the connection over time. Think of it like adding salt to perfectly seasoned dish. Just don't do it!

Q: What if my wire strands are really frayed and difficult to manage?A: Try using a small piece of heat shrink tubing to hold the strands together while you crimp. Slide the tubing over the stripped wire, leaving a small portion exposed for the connector. Crimp as usual, then shrink the tubing for a secure and tidy finish. This is a much better option than tinning.

Q: How do I know if my crimp is good?A: A good crimp should be mechanically sound — meaning you shouldn't be able to easily pull the wire out of the connector. The connector should also be properly deformed around the wire, creating a tight, gas-tight seal. Visually inspect the crimp and give it a gentle tug test. If in doubt, re-crimp!

Q: I have some old wires that are corroded. Can I tin them to make them usable again?A: It's generally best to replace corroded wires entirely. Corrosion can weaken the wire and increase resistance, leading to potential failures. If you absolutely must use a corroded wire, clean it thoroughly with a wire brush or sandpaper before tinning (very lightly!) and crimping. But again, replacement is the preferred option.