Brilliant Strategies Of Tips About How To Make A Motor More Powerful

Unleash the Beast

1. Understanding the Quest for Power

So, you're looking to pump up the volume on your motor, huh? We've all been there. Whether it's for a souped-up RC car, a DIY project that demands extra oomph, or just plain curiosity, the desire for more power is a universal one. But before we dive into the how-to, let's get something straight: "power" is a broad term. We're talking about increasing torque (rotational force), speed (RPM), or both. And of course, making sure the motor can handle the extra strain without, you know, exploding. We want a beast, not a bonfire.

Think of it like this: Your motor is a tiny athlete. You want them to lift heavier weights (torque) and run faster (RPM). But you can't just yell at them to do it. You need to train them properly, give them the right fuel, and make sure they don't pull a muscle. That's what we're going to cover. We'll explore several methods for coaxing more performance out of your electric motor, starting with the basics and moving towards more advanced techniques.

Before charging ahead, it is paramount to understand the original intended design parameters of the motor. Pushing any system beyond its engineering limits can lead to premature wear, damage, or even catastrophic failure. So, let's temper ambition with a dose of realism and a healthy respect for the principles of physics. After all, we're not trying to break the laws of the universe, just bend them a little to our advantage!

Safety first, always! Before you begin tinkering, disconnect the power source. Working with electricity can be dangerous, and we want you to keep all your fingers. Remember that experimenting with electrical components involves inherent risks, and any modifications should be undertaken with extreme caution and at your own risk. Consider yourself warned!

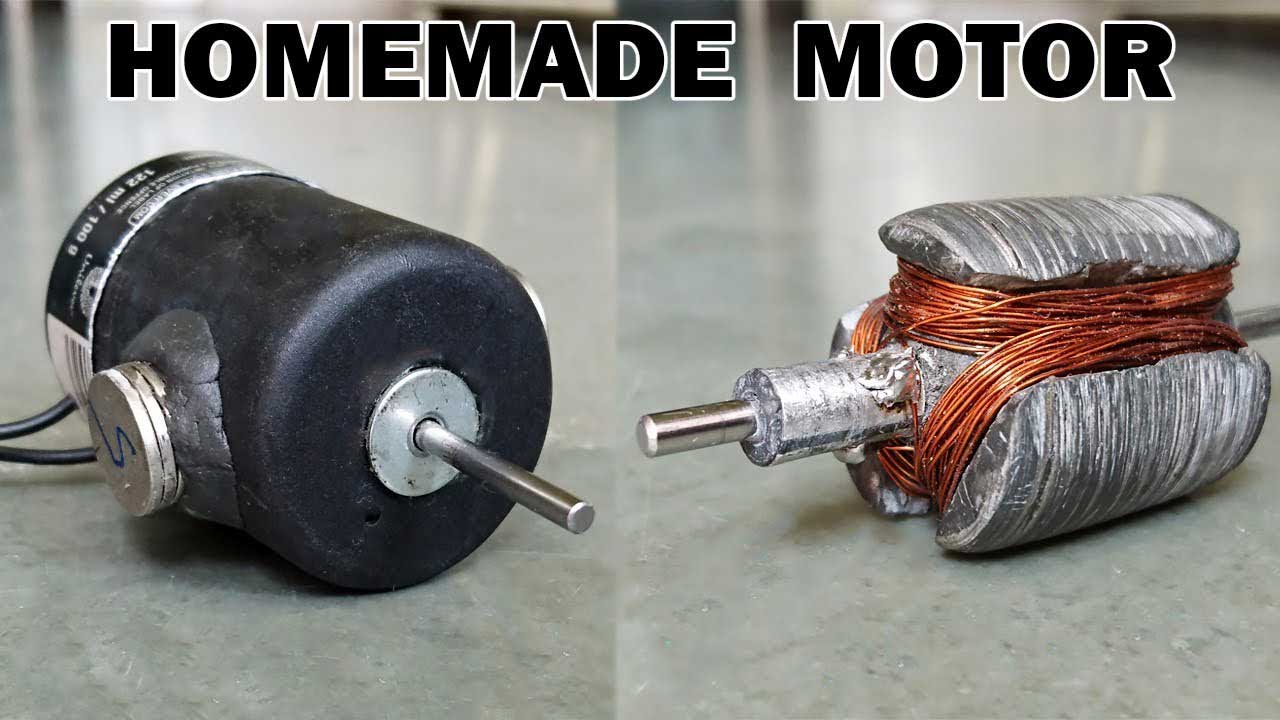

How To Make A Motor Car At Home Using DC DIY

Tweaking the Voltage

2. Voltage

One of the most straightforward ways to increase a motor's speed is to increase the voltage. More voltage generally translates to higher RPMs. However, this is also where things can get tricky. Motors are designed to operate within a specific voltage range, and exceeding that range can lead to overheating, burnout, and a very unhappy motor. It's like feeding a toddler an entire pizza; sure, they might enjoy it for a minute, but the aftermath won't be pretty.

If you're going to experiment with voltage, do it in small increments and monitor the motor's temperature closely. Use a multimeter to measure the current draw. If the current starts to spike dramatically, you're pushing the motor too hard. Think of it like a speedometer in your car; redlining it for too long is never a good idea.

Also, consider the motor's insulation class. This tells you how much heat the motor's windings can withstand before the insulation breaks down. Exceeding the insulation's temperature rating is a surefire way to shorten the motor's lifespan. The manufacturer's specifications are your friend here. Don't ignore them.

And let's not forget about the components powering the motor. Are your batteries or power supply up to the task? A weak power source can limit the motor's performance just as much as the motor itself. Make sure you have a power supply that can deliver the necessary voltage and current without struggling.

Gear Ratios

3. Gears

Sometimes, increasing speed isn't the answer. Sometimes, you need more grunt, more torque. That's where gear ratios come in. Gears act like levers, trading speed for torque (or vice versa). A lower gear ratio (e.g., 2:1) will increase torque but reduce speed, while a higher gear ratio (e.g., 1:2) will increase speed but reduce torque. It's a balancing act, like choosing between a sprint and a marathon. Which do you need for your application?

Choosing the right gear ratio depends entirely on what you're trying to accomplish. If you're driving a heavy load or climbing a steep incline, you'll want a lower gear ratio. If you're trying to achieve high speeds on a level surface, a higher gear ratio might be more appropriate. Imagine trying to tow a boat with a bicycle in top gear — it would be incredibly difficult. But switch to a lower gear, and suddenly, it becomes much more manageable.

When changing gear ratios, be mindful of the stress you're putting on the motor and the gears themselves. Using excessively low gear ratios can overload the motor, causing it to overheat or stall. Similarly, using excessively high gear ratios can strip the gears or cause them to wear out prematurely. Quality gears are a must if you're planning to push the limits. Don't skimp on this part; cheap gears will quickly become a headache.

Don't forget to consider the overall efficiency of the gear system. Each gear mesh introduces a small amount of friction, which reduces the overall efficiency. Too many gears or poorly lubricated gears can significantly reduce the amount of power that actually reaches the load. Regular lubrication is essential for maintaining efficiency and prolonging the life of the gears.

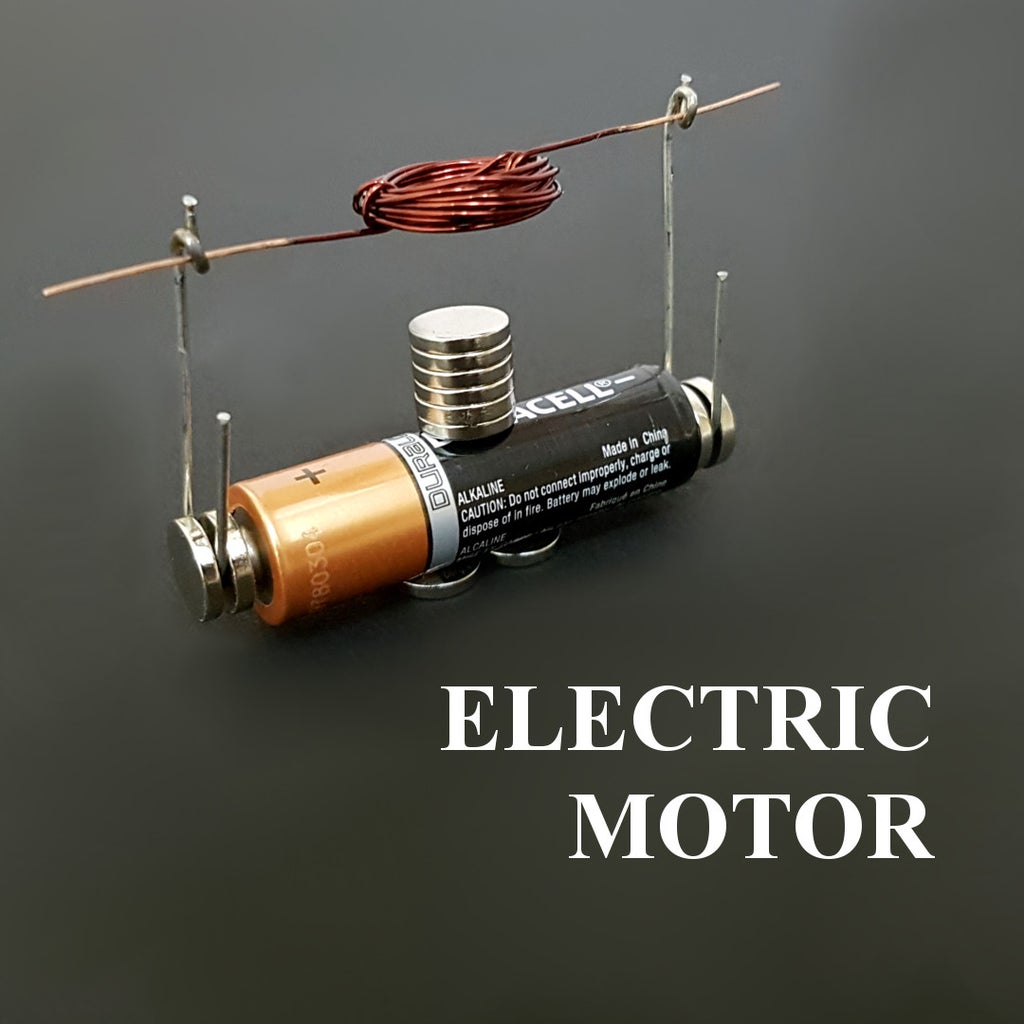

Primitive Motor How To Make A DC DIY ELECTRIC MOTOR YouTube

Optimizing the Motor's Environment

4. Environment Matters

A happy motor is a cool motor. Overheating is the enemy of performance and longevity. Heat increases resistance, reduces efficiency, and can eventually lead to catastrophic failure. Think of it like running a marathon in a sauna; you're not going to perform your best. Proper ventilation and cooling are crucial for keeping your motor running strong.

Consider adding a heat sink to the motor. Heat sinks are designed to dissipate heat away from the motor's surface, keeping it cooler. You can also use a fan to blow air across the motor. Even a small fan can make a significant difference in operating temperature. Experiment with different cooling solutions to find what works best for your application.

Dust, dirt, and debris can also negatively impact motor performance. These contaminants can clog the motor's ventilation openings, reducing its ability to cool itself. They can also cause friction and wear on the motor's internal components. Regularly cleaning the motor can help to keep it running smoothly and efficiently.

Consider the ambient temperature in which the motor is operating. If you're using the motor in a hot environment, it will be more susceptible to overheating. In extreme cases, you may need to use a more sophisticated cooling system, such as a liquid-cooled heat sink or even a small air conditioner. It might sound extreme, but if you're serious about maximizing performance, it's worth considering.

Advanced Techniques

5. Beyond the Basics

If you've tried all the above and you're still craving more power, it's time to venture into more advanced techniques. These methods often involve modifying the motor's internal components or using more sophisticated control systems. Proceed with caution, as these techniques can be more complex and require specialized knowledge and equipment.

One option is to rewind the motor's stator. Rewinding allows you to change the number of turns of wire, the wire gauge, and the winding pattern. This can be used to optimize the motor for higher speed or higher torque. However, rewinding a motor is a delicate process that requires precision and expertise. It's not something you should attempt without proper training and experience.

Another advanced technique is to use a field-oriented control (FOC) system. FOC systems use sophisticated algorithms to precisely control the motor's current and voltage, optimizing its performance and efficiency. FOC systems can provide significant improvements in torque, speed, and overall efficiency, but they also require a deep understanding of motor control theory and programming.

Finally, consider upgrading the motor's bearings. High-quality bearings can reduce friction and improve efficiency, allowing the motor to run smoother and faster. Ceramic bearings are a popular choice for high-performance applications due to their low friction and high heat resistance. However, they are also more expensive than traditional steel bearings.