One Of The Best Info About Do Capacitors Have Continuity

Understanding The Microfarad Capacitor A Comprehensive Guide

Capacitors and Continuity

1. Understanding the Basics

So, you're wondering if capacitors have continuity, huh? It's a fair question, especially if you're poking around with a multimeter and getting some funky readings. The short answer is: it's complicated! Unlike resistors, which offer a consistent level of opposition to current flow, capacitors behave a bit differently. Think of them like tiny rechargeable batteries — they store energy, and that storage process affects how they appear to a continuity test.

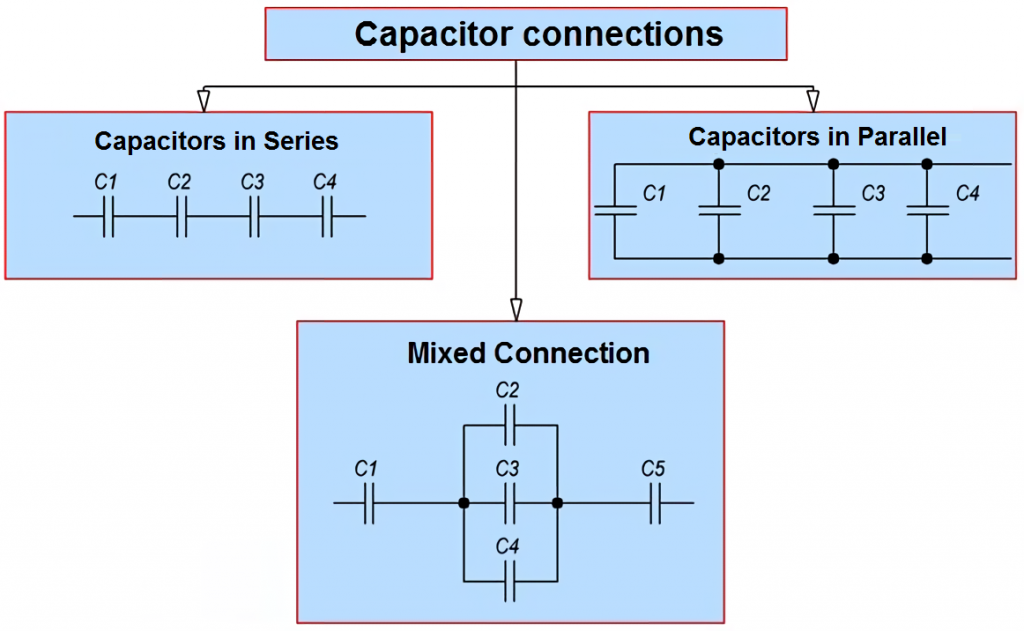

A capacitor, in its simplest form, is two conductive plates separated by an insulator (called a dielectric). When voltage is applied, electrons build up on one plate, creating an electrical field. This stored energy can then be released later. The ability of a capacitor to store charge is measured in Farads (F). Now, before you go off thinking about batteries, remember capacitors discharge a lot faster!

Imagine trying to fill a bucket with water, but the bucket has a tiny hole. Thats kind of what happens when you apply a voltage to a capacitor. It starts filling up with electrons (charging), but eventually, it reaches its maximum capacity. Once its full, it stops the flow, just like that leaky bucket. So, how does this leaky bucket analogy tie into continuity tests? Let's find out.

Essentially, continuity testing involves sending a small current through a component and seeing if it can make it to the other side. If there's a clear path, the multimeter beeps (or displays a low resistance value), indicating continuity. However, a capacitor's charging behavior throws a wrench into this process. That initial charging phase can trick you into thinking there's continuity when there really isn't.

The Multimeter's Perspective

2. Why a Continuity Test Can Be Misleading

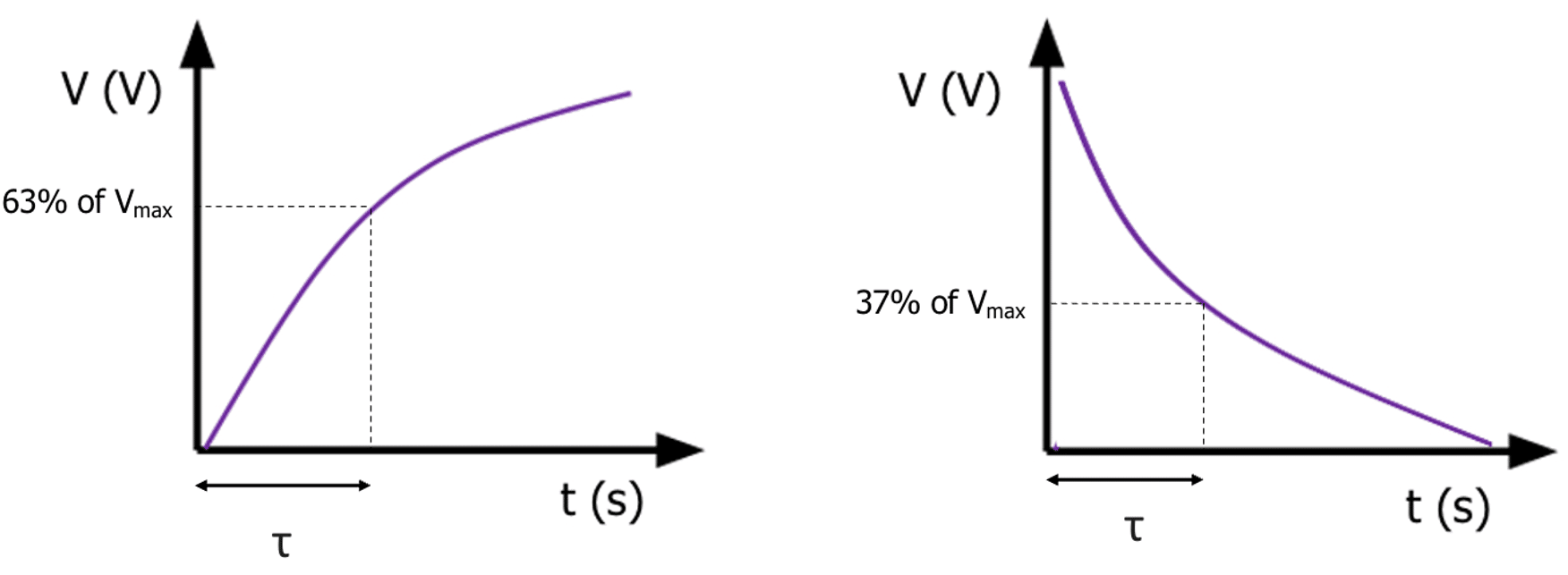

When you stick your multimeter probes across a capacitor in continuity mode, you might see the resistance start low and then gradually increase. This is because the capacitor is initially acting like a short circuit as it charges. The multimeter is sending current, and the capacitor is happily sucking it up. The meter shows nearly zero resistance, leading you to think "Aha! Continuity!".

But, as the capacitor charges, its internal resistance increases, and the current flow decreases. The multimeter reading will gradually rise until it reaches a very high resistance (ideally, infinity) or an "OL" (overload) indication. This happens because the capacitor is now "full" and blocking any further current flow. So, that initial "beep" or low resistance reading was just a temporary phenomenon.

So, the critical thing to remember is that this temporary continuity is not a true indication of whether the capacitor is good or bad. A capacitor that appears to have continuity constantly, even after a significant charging time, is likely shorted and needs to be replaced. Think of it like a bucket with a giant hole in the bottom; it can't hold water (charge) and will always appear "empty" to the multimeter.

Essentially, a brief "continuity" reading followed by increasing resistance is actually a good sign. It suggests the capacitor is at least attempting to charge. The absence of any initial reading could indicate an open capacitor, while a persistent low resistance reading indicates a shorted one. Testing a capacitor is more nuanced than just checking for a simple yes/no continuity.

Beyond Continuity

3. Using a Multimeter More Effectively

Forget relying solely on the continuity test. A better approach involves using a multimeter's capacitance setting (if it has one). This allows you to directly measure the capacitance value of the component. Compare this measured value to the capacitor's stated capacitance (usually printed on the component). A significant deviation suggests a problem.

Before testing, always discharge the capacitor. You can do this by briefly shorting the terminals with a resistor (something around 1k ohm is usually safe). This prevents any stored voltage from damaging your multimeter or giving you a false reading. Safety first, always!

Another useful test is to measure the ESR (Equivalent Series Resistance) of the capacitor. ESR is the internal resistance of the capacitor and increases as the capacitor ages and degrades. Specialized ESR meters are available, but some advanced multimeters also offer this functionality. A high ESR can indicate a failing capacitor, even if the capacitance value seems within range.

Lastly, visual inspection is surprisingly valuable. Look for signs of bulging, leaking, or discoloration on the capacitor. These are often clear indicators of failure. Think of it like checking your tires; a visual inspection can often reveal problems that other tests might miss.

Common Capacitor Problems and What They Mean

4. Decoding Capacitor Issues

Several things can go wrong with capacitors. Shorted capacitors, as we mentioned, are a common issue. This happens when the dielectric breaks down, creating a direct connection between the plates. This results in a constant low resistance reading and, usually, a non-functional circuit. Consider it as the capacitor having an electrical heart attack!

Open capacitors occur when the internal connections break, preventing any charge storage. This manifests as no reading on a capacitance meter and no initial "continuity" indication when tested. It's like the capacitor has simply gone silent.

Leaky capacitors exhibit excessive current leakage through the dielectric. This leads to inaccurate capacitance values and can cause instability in the circuit. Imagine a leaky pipe; it still works, but not as efficiently as it should. ESR often increases with leaky capacitors.

Finally, capacitors can simply dry out over time, especially electrolytic capacitors. The electrolyte fluid inside evaporates, reducing the capacitance and increasing ESR. This is a gradual process but eventually leads to component failure. It's like a plant slowly withering due to lack of water.

FAQs About Capacitors and Continuity

5. Your Burning Questions Answered

Let's tackle some of the most common questions surrounding capacitors and continuity tests.

Q: My multimeter beeps briefly when I touch the probes to a capacitor, is it broken?

A: Probably not! As we've covered, that initial beep is likely the capacitor charging. The resistance should then increase. If it beeps continuously, then you might have a shorted capacitor.

Q: Can I test a capacitor while it's still in the circuit?

A: It's generally recommended to remove the capacitor from the circuit for accurate testing. Other components in the circuit can interfere with the readings. Disconnecting one leg is usually sufficient, but completely removing it is best.

Q: What's the deal with polarized capacitors? Do they affect continuity testing?

A: Polarized capacitors (like electrolytic capacitors) have a positive and negative terminal. Connecting them backward in a circuit can damage them. When testing with a multimeter on capacitance mode, it's important to respect the polarity. However, for a quick continuity test (though not recommended as a definitive test), polarity isn't as crucial, but be mindful of potential damage if you apply significant voltage incorrectly.

Q: Is there a specific capacitance range where continuity testing is more reliable?

A: No, continuity testing isn't reliably for any capacitance range when trying to determine if a capacitor is good. Focus on capacitance measurements and ESR if possible.