Amazing Info About What Is Wire Identification

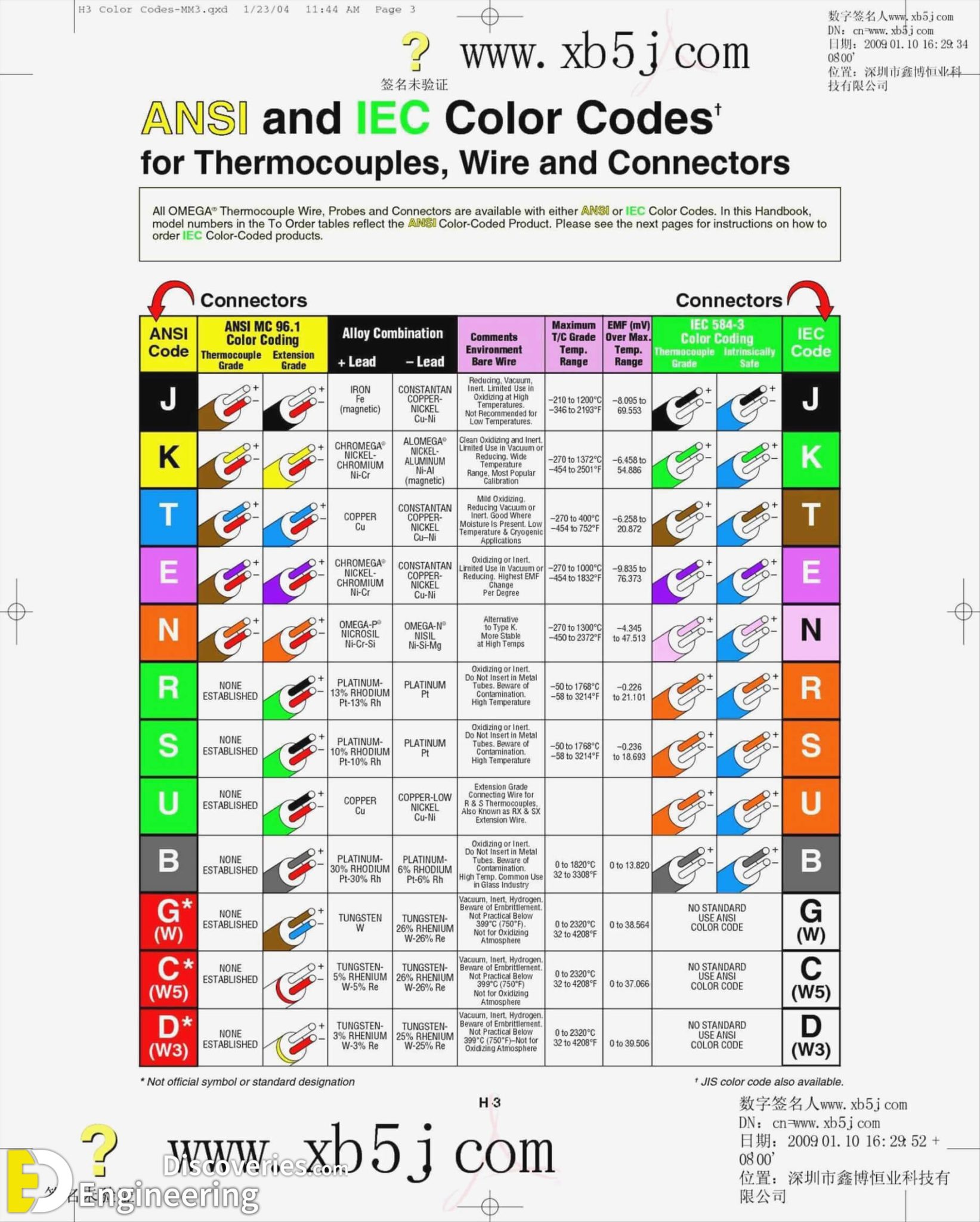

Electrical Wiring Color Codes

Decoding the Mystery

Ever stared into a tangle of wires and felt a rising sense of panic? You're not alone! Figuring out what wire does what is a common challenge, whether you're tackling a DIY home project, diagnosing a car issue, or just trying to sort out the spaghetti behind your computer. That's where wire identification comes to the rescue. Think of it as giving each wire its own name tag, so you know exactly what it's supposed to be doing.

At its core, wire identification is the process of labeling or marking electrical wires and cables to indicate their purpose, function, or destination. This helps electricians, technicians, and even the average homeowner quickly and accurately identify each wire without having to trace it back to its source every single time. Imagine trying to debug a complex electronic system without knowing which wire controls the power supply — pure chaos!

Essentially, its about avoiding costly mistakes, preventing electrical hazards, and saving a whole lot of time. Proper wire identification ensures safety and efficiency, especially when working with complex electrical systems. It's like having a roadmap instead of wandering aimlessly in a labyrinth.

But wire identification isn't just about slapping a label on something. It also involves selecting appropriate identification methods and adhering to industry standards and best practices. The types of labels, markings, and systems used can vary depending on the application, environment, and regulations. Selecting the right method is just as crucial as identifying correctly, to prevent fading, tearing, or simply falling off.

1. Why Bother with Wire Identification? The Benefits Unveiled

Okay, so we know what it is, but why should you care? The benefits of wire identification are actually quite extensive. First and foremost, its a huge safety measure. By correctly identifying wires, you reduce the risk of electrical shocks, short circuits, and other potentially dangerous situations. Imagine rewiring a light fixture and accidentally crossing the neutral and hot wires... not a fun experience!

Wire identification also significantly reduces troubleshooting time. Instead of spending hours tracing wires, you can quickly pinpoint the problem and get it fixed. This is especially important in industrial settings where downtime can be incredibly expensive. In essence, time is money, and with good wire identification, you save boatloads of it.

Beyond safety and efficiency, wire identification also makes maintenance and repairs easier. Clear labeling simplifies future work and reduces the likelihood of errors. Think about it: if someone else needs to work on the system later, they'll be able to understand the wiring without having to start from scratch.

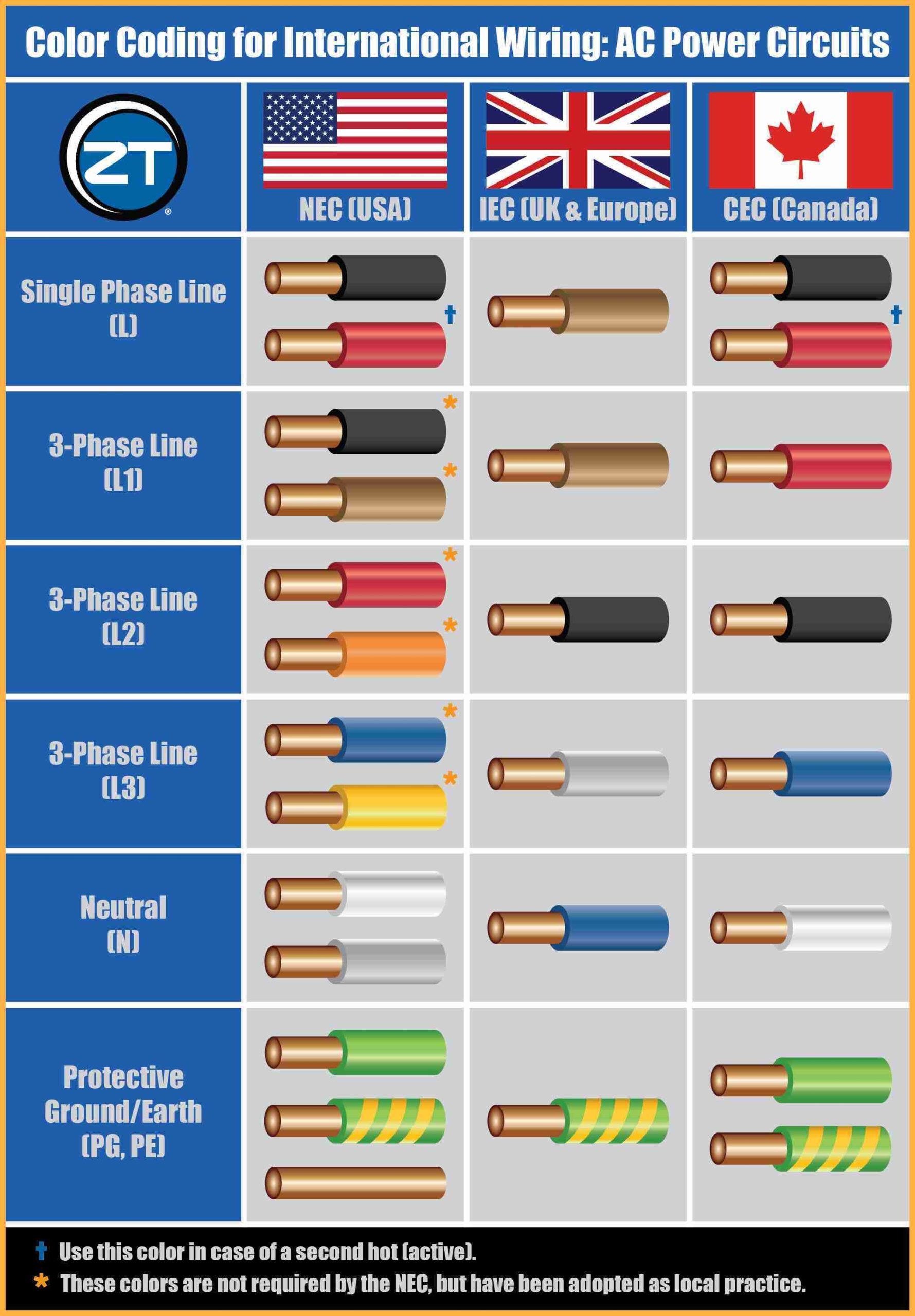

Finally, it helps compliance with regulatory standards. Many industries and regions have specific requirements for wire identification to ensure safety and prevent hazards. Following these standards is not only responsible but also legally necessary in some cases. Avoiding a fine is always a good thing!

Wiring Color Codes Coding, Infographic

Methods of Wire Identification

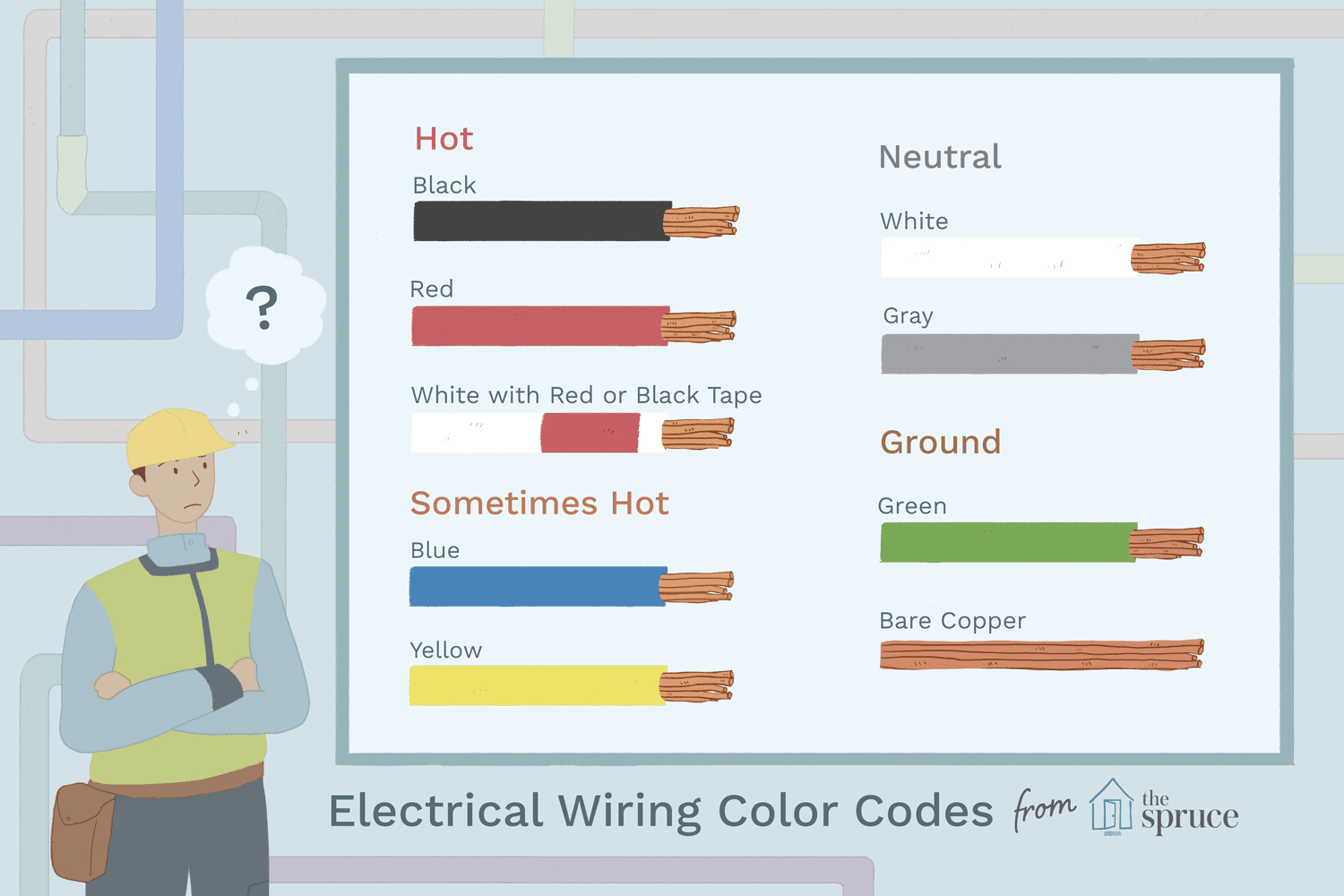

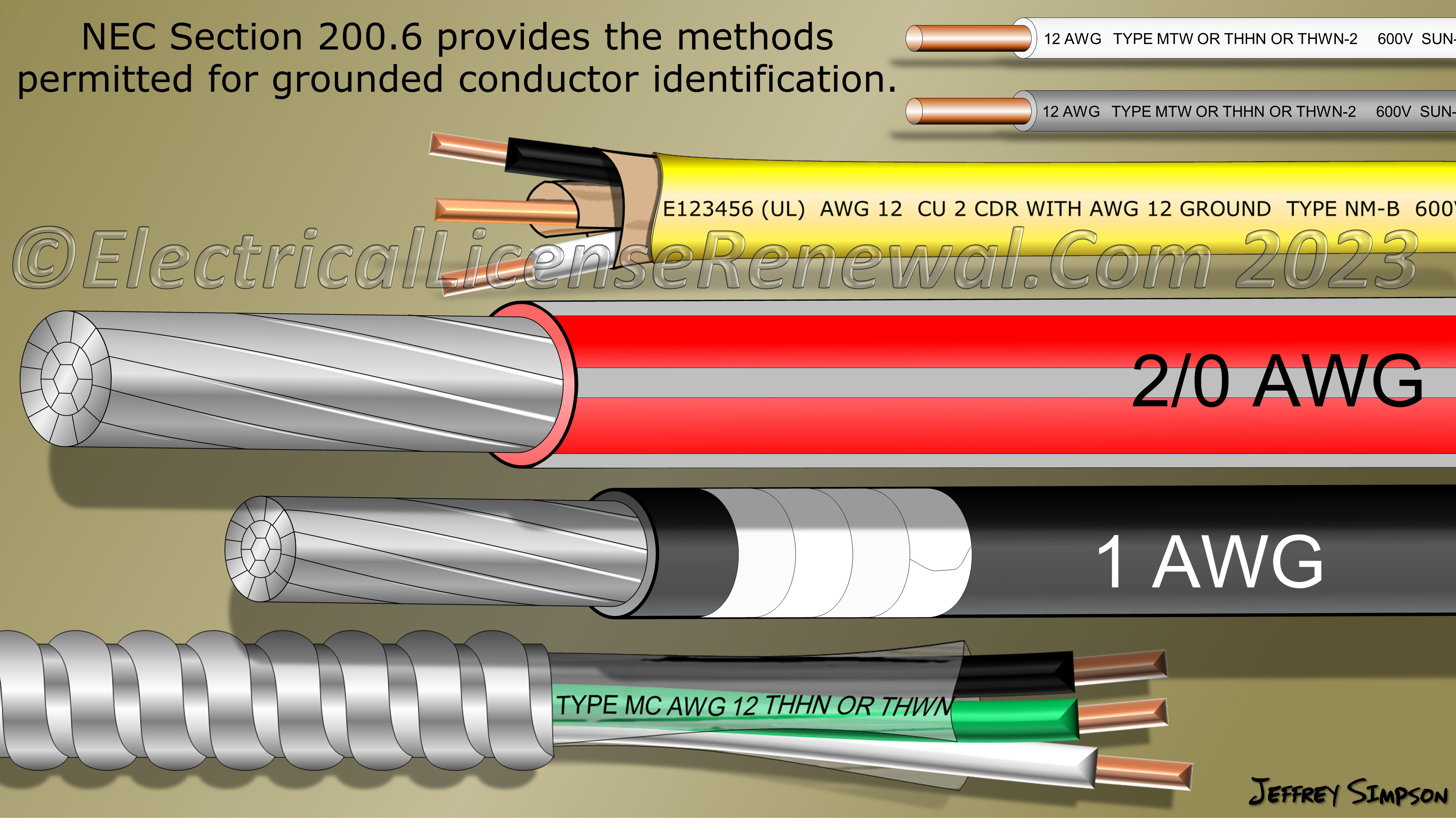

So, how do we actually do wire identification? There's a surprisingly wide range of methods available, each with its own advantages and disadvantages. The simplest approach involves using colored wires. Different colors are assigned to different functions, making it easy to identify wires at a glance. For example, in household wiring, black is typically used for hot wires, white for neutral wires, and green for ground wires. However, color-coding alone isn't always enough, especially in complex systems with many wires.

Wire marking sleeves are another common method. These are small tubes that slip over the wire and have printed characters indicating the wire's function. They are durable and easy to install, making them a popular choice in many applications. You can get heat-shrinkable sleeves too that hug the wire snugly when heated.

Wire labels, either pre-printed or created with a label maker, are also widely used. These can be attached to wires using adhesive or cable ties. Modern label makers often allow you to create custom labels with barcodes or QR codes, making it even easier to track and manage wires. The sky really is the limit on labeling now.

For more advanced applications, direct wire marking is sometimes used. This involves directly printing information onto the wire using specialized printers or laser marking systems. This method provides permanent and highly legible markings, ideal for harsh environments. Think of military applications and the like, needing a durable marking that won't fade or break off.

2. Choosing the Right Method

Selecting the right wire identification method depends on a variety of factors. The environment in which the wires will be used is a key consideration. Will they be exposed to extreme temperatures, chemicals, or moisture? If so, you'll need to choose a method that is durable and resistant to these conditions. Certain labels and inks simply won't cut it in harsh environments.

The complexity of the wiring system is another factor. For simple systems with few wires, color-coding or simple labels may be sufficient. However, for complex systems with many wires, more sophisticated methods like wire marking sleeves or direct wire marking may be necessary.

Budget also plays a role. Some methods, like direct wire marking, can be quite expensive, while others, like color-coding, are relatively inexpensive. Balance cost with the necessary durability and legibility needed for the application. Don't cheap out on safety!

Finally, industry standards and regulations may dictate which methods are acceptable. Make sure to check the relevant standards and regulations before making a decision. Compliance is non-negotiable.

Best Practices for Wire Identification

Even with the right methods in place, its important to follow best practices to ensure effective wire identification. Always use clear and legible markings. Avoid using ambiguous abbreviations or symbols that could be misinterpreted. The goal is clarity, so make sure the labels are easy to read.

Document your wire identification system. Keep a record of which colors, labels, or markings correspond to which functions. This will make it easier to troubleshoot and maintain the system in the future. A detailed wire map is a valuable asset.

Use consistent markings throughout the system. This will prevent confusion and ensure that everyone understands the wiring. Consistency is key to minimizing errors.

Regularly inspect and maintain your wire identification system. Replace any damaged or faded labels to ensure that they remain legible. It's better to prevent issues than to react to them after it causes problems.

3. The Future of Wire Identification

The world of wire identification is constantly evolving, with new technologies and innovations emerging all the time. One promising trend is the use of RFID (Radio-Frequency Identification) tags to track and manage wires. RFID tags can be embedded in wires or attached to labels, allowing you to wirelessly identify and track wires using a handheld scanner. This technology can significantly improve efficiency and accuracy in large-scale wiring systems.

Another trend is the increasing use of augmented reality (AR) to assist with wire identification. AR apps can overlay information about wires onto a live video feed, making it easier to identify and troubleshoot them. Imagine pointing your smartphone at a jumble of wires and instantly seeing what each one is connected to — pretty cool, right?

Smart labels with built-in sensors are also gaining popularity. These labels can monitor the temperature, humidity, and other environmental conditions around the wires, providing valuable insights into the health and performance of the system. Data driven insight can save a lot of maintenance cost and time.

As technology continues to advance, we can expect even more sophisticated and efficient wire identification solutions to emerge in the future. Who knows, maybe one day we'll have self-labeling wires that automatically identify themselves!

Australian Electrical Wire Color Code

Frequently Asked Questions (FAQs) About Wire Identification

4. Q

A: One common mistake is using illegible or ambiguous markings. Another is failing to document the wire identification system. And of course, mixing up colors or mislabeling wires can also lead to problems.

5. Q

A: Not necessarily. The type of label you use should be appropriate for the environment in which the wires will be used. Consider factors like temperature, humidity, and exposure to chemicals.

6. Q

A: Yes, many industries and regions have specific standards for wire identification. These standards are designed to ensure safety and prevent hazards. Be sure to check the relevant standards and regulations for your specific application.

7. Q

A: While helpful, color coding may not always be sufficient, especially in complex systems. Supplementing color coding with labels or other markings is generally recommended.

200.6 Means Of Identifying Grounded Conductors.