Who Else Wants Tips About How Many Rpm Is A 2 Pole Motor

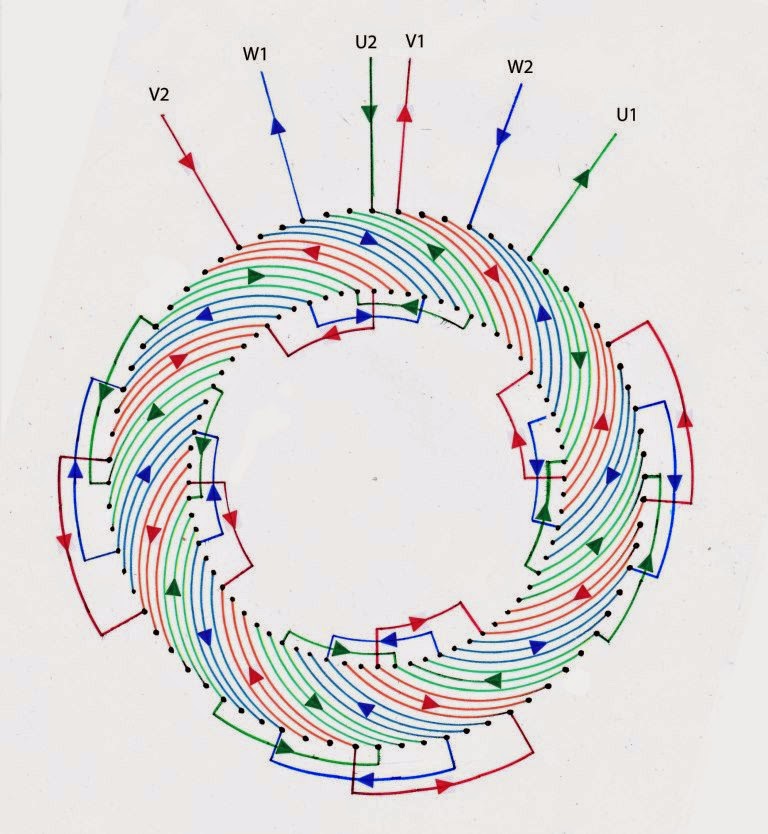

Two Speed 3 Phase Motor Winding Diagram

Unlocking the Secrets of 2-Pole Motor RPMs

1. Decoding Motor Speed

Ever wondered how fast things spin? Especially when it comes to motors? Lets dive into the world of 2-pole motors and unravel the mystery of their rotations per minute, or RPM. Think of it as figuring out the pace of a tiny, tireless athlete inside your machinery. It's not just about numbers; it's about understanding the rhythm of the machine. A 2-pole motor is a common type, and its speed is pretty straightforward, but understanding the basics is always a good idea.

The RPM of a 2-pole motor isn't some arbitrary figure plucked from thin air. It's determined by the frequency of the power supply and the number of poles in the motor. In simple terms, the frequency tells the motor how quickly to switch directions, and the poles dictate how many times the magnetic field needs to rotate for each complete rotation of the motor shaft. So, let's get into the meat of calculating this speed and what factors are at play.

Imagine the motor as a dancer. The power supply provides the music, and the motor's poles tell it how to move. A 2-pole motor, in this analogy, is a pretty energetic dancer. It can achieve some impressive speeds, but like any dancer, there are constraints. The power supply has to be consistent, and the motor itself has to be well-maintained to reach its optimal performance. Its a delicate balancing act between power, design, and load.

So, why does understanding the RPM of a 2-pole motor even matter? Well, it's crucial for selecting the right motor for a specific application. A motor that's too slow won't get the job done, and one that's too fast can cause damage or inefficiency. Finding the sweet spot ensures your machinery operates smoothly and efficiently, like a well-oiled, perfectly synchronized machine. It's all about making sure the dancer is moving at the right tempo!

3 Phase 6 Pole 960 Rpm Motor Winding Connection Diagram54 Slot 18 Coil

The Formula for Speed

2. Calculating Synchronous Speed

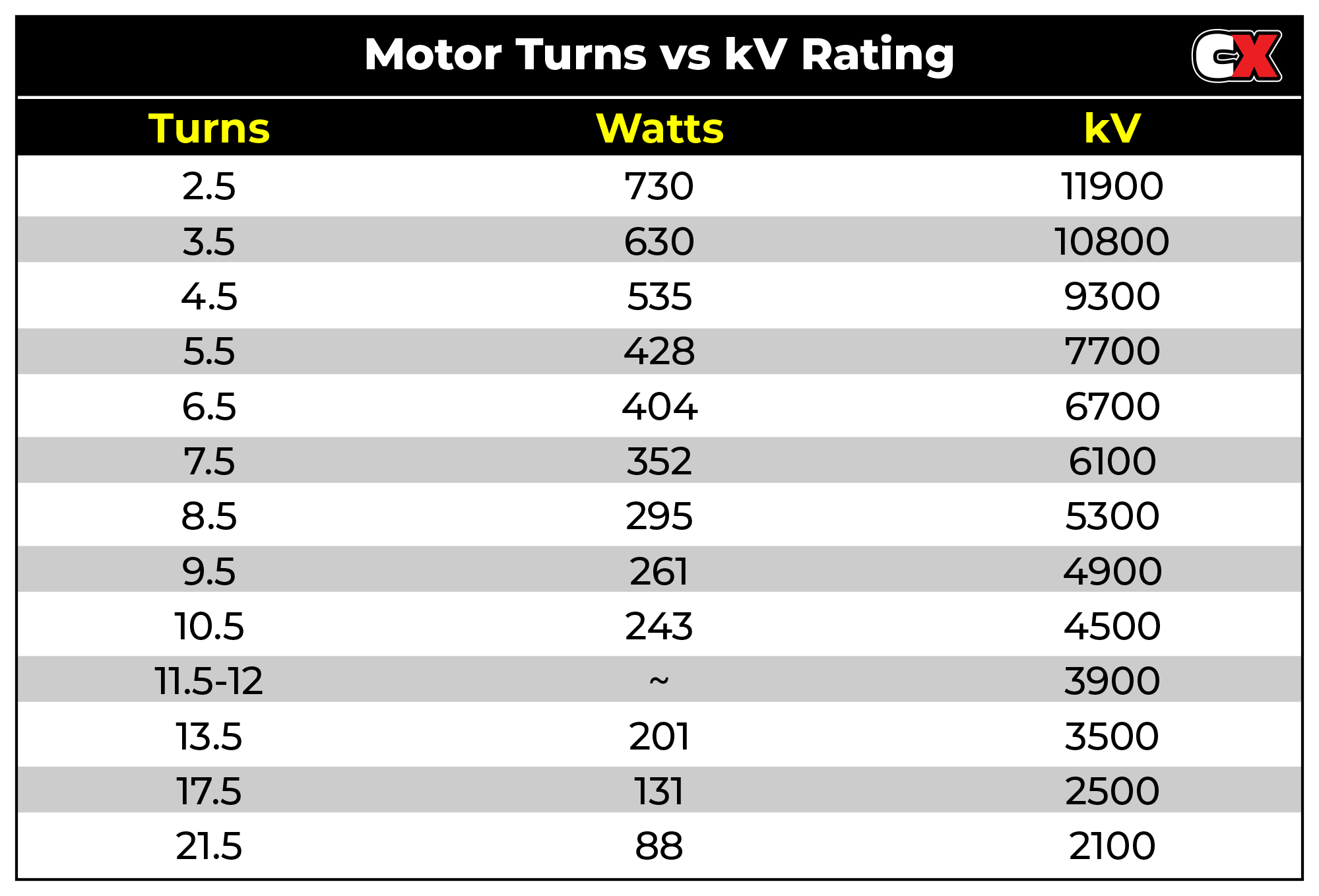

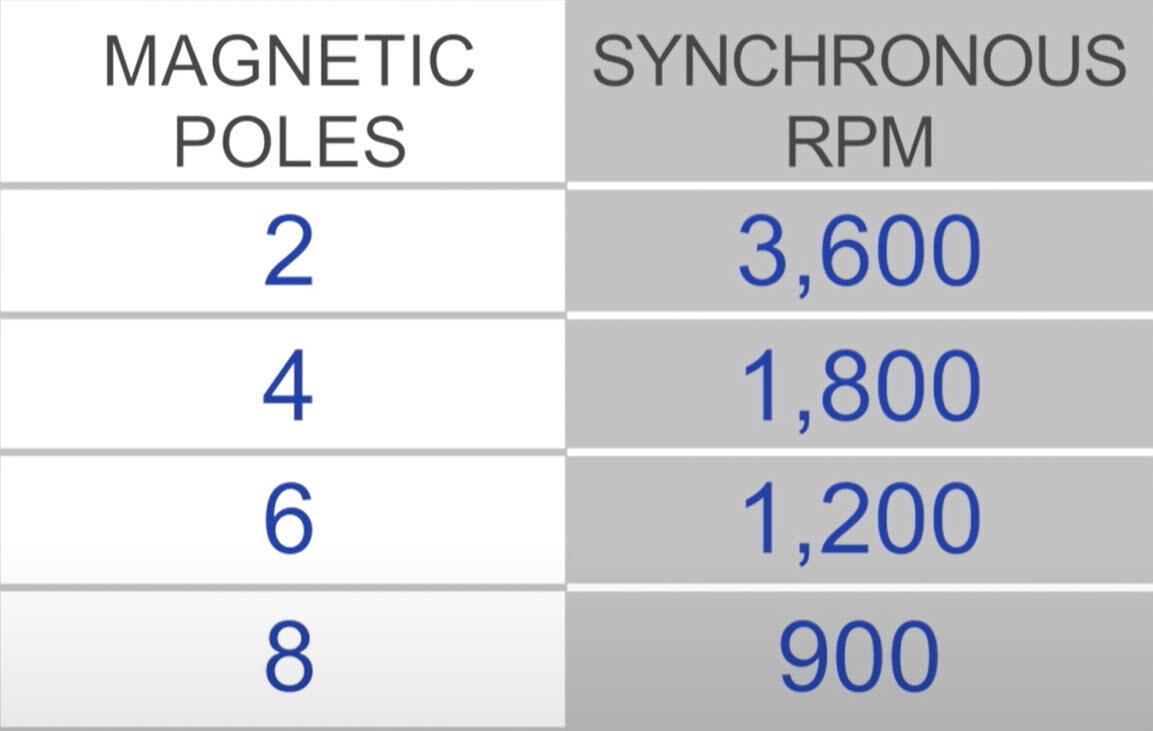

Alright, let's get a little technical, but don't worry, we'll keep it simple. The synchronous speed of a 2-pole motor is calculated using a formula. The magic formula is: RPM = (120 x Frequency) / Number of Poles. Frequency is measured in Hertz (Hz), which represents cycles per second. In many countries, the standard frequency is 50 Hz, while in others (like the US), it's 60 Hz.

For a 2-pole motor operating on a 60 Hz power supply, the calculation is: RPM = (120 x 60) / 2 = 3600 RPM. Now, if we were to use a 50 Hz power supply, the calculation would be: RPM = (120 x 50) / 2 = 3000 RPM. See? Not so scary, is it? Its just a matter of plugging in the numbers and letting the math do its thing.

It's crucial to remember that this calculated RPM is the synchronous speed. This is the theoretical maximum speed. In reality, motors rarely reach this exact speed due to factors like load and internal losses, which brings us to the concept of "slip." So, even though the formula gives us a clean number, real-world performance is a bit more nuanced.

Think of it like driving a car. The speedometer might say you can reach a certain top speed, but factors like traffic, hills, and the weight of your passengers can affect your actual speed. Similarly, the synchronous speed is the ideal, but the actual operating speed can vary depending on the application and the motor's design. Understanding this distinction is key to selecting the correct motor for your needs.

Electric Motor Frame Conversion Chart At Amy Yates Blog

Slip

3. Understanding Real-World Motor Speed

Ah, slip. It sounds like something you'd do on a banana peel, but in the world of motors, it's the difference between the synchronous speed and the actual rotor speed. It's caused by the load on the motor — the harder the motor works, the more it slips. It's an inherent characteristic of induction motors, which are very common.

This "slip" is usually expressed as a percentage. A typical induction motor might have a slip of around 2-5%. So, if your 2-pole motor has a synchronous speed of 3600 RPM (on a 60Hz supply), the actual speed under load might be closer to 3420-3528 RPM. Its a slight drop, but it's an important one to consider for precise applications.

Why does slip happen? Well, the rotor (the spinning part) needs to experience a changing magnetic field to generate torque. If the rotor spun at the exact same speed as the rotating magnetic field, there would be no relative motion, and thus, no torque. So, slip is actually necessary for the motor to function! It's a bit counterintuitive, but that's how these motors roll (pun intended!).

Ignoring slip can lead to miscalculations and potentially choosing the wrong motor for the job. It's like assuming your car will always get the advertised gas mileage, without accounting for traffic, weather, or your lead foot. By understanding slip, you can more accurately predict the real-world performance of your motor and ensure it's a good fit for its intended application. It is one of the critical elements when choosing the right 2 pole motor.

Factors Affecting Motor Speed Beyond the Basics

4. External Influences on Motor Performance

So, weve covered the formula and the sneaky concept of slip. But what else can affect a 2-pole motor's RPM? Well, voltage fluctuations can play a role. If the voltage dips too low, the motor might struggle to maintain its speed, especially under load. Think of it like trying to run a marathon on low blood sugar — you'll slow down eventually. Stable and consistent voltage is key for optimal performance.

Temperature also has an impact. Overheating can reduce the motor's efficiency and lifespan. Excessive heat can damage the insulation and windings, leading to a drop in performance and, eventually, failure. Proper cooling and ventilation are crucial for keeping the motor within its optimal operating temperature range. Don't let your motor get heatstroke!

The load itself is a major factor. A heavier load requires more torque, which can lead to increased slip and a lower RPM. The type of load also matters. A load that varies significantly can cause the motor to constantly adjust its speed, which can put stress on the motor and reduce its overall efficiency. Choosing the right motor size and type for the specific load is essential.

Finally, the motor's condition plays a role. Worn bearings, damaged windings, or other mechanical issues can all affect its ability to reach and maintain its rated speed. Regular maintenance and inspections can help identify and address these issues before they become major problems. Think of it as giving your motor a regular check-up to keep it running smoothly for years to come.

Why Accurate RPM Matters

5. The Importance of Precision

Alright, so you know how to calculate the RPM and understand the factors that can influence it. But why does all of this matter in the real world? Well, imagine you're designing a conveyor belt system. If the motors driving the belt are running too fast or too slow, the entire system could malfunction, leading to bottlenecks, spills, and general chaos. Accuracy is key to ensuring smooth and efficient operation.

In manufacturing processes, precise RPM control is essential for maintaining product quality. For example, in textile manufacturing, the speed of the spinning machines directly affects the yarn's quality. Too much variation can result in uneven or weak yarn, leading to defects in the final product. Consistent RPM ensures consistent product quality.

Even in simpler applications, like fans and pumps, RPM accuracy matters. A fan running too slow won't provide adequate cooling, and a pump running too slow won't deliver enough fluid. Matching the motor's RPM to the specific requirements of the application is crucial for achieving optimal performance and efficiency. It's like choosing the right gear for climbing a hill on a bicycle — the right speed makes all the difference.

Furthermore, understanding and controlling motor RPM can lead to significant energy savings. By optimizing the motor's speed for the specific load, you can reduce energy waste and lower your operating costs. This is especially important in industrial settings where motors consume a significant portion of the total energy. Efficient motor operation is not only good for your bottom line but also for the environment. So, it's a win-win!

FAQ

6. Frequently Asked Questions

Q: What happens if I overload a 2-pole motor?A: Overloading a motor can cause it to overheat, which can damage the windings and shorten its lifespan. It can also lead to reduced speed and efficiency. Basically, it's not a good idea. Think of it like trying to lift something that's way too heavy — you'll strain yourself and probably drop it.

Q: Can I change the speed of a 2-pole motor?A: Yes, you can, but it's not as simple as turning a dial. Variable Frequency Drives (VFDs) are commonly used to control the speed of AC motors. These devices alter the frequency of the power supply, which in turn changes the motor's speed. Just be aware that changing the speed can also affect the motor's torque.

Q: Are 2-pole motors suitable for all applications?A: Not necessarily. 2-pole motors are generally used for applications that require high speeds. For applications that require lower speeds or higher torque, motors with more poles might be more suitable. It all depends on the specific requirements of the job.