Beautiful Work Info About What Is MBOM In SAP

![How To Automate The Software Bill Of Materials [SBOM] Reflectiz How To Automate The Software Bill Of Materials [SBOM] Reflectiz](https://www.reflectiz.com/wp-content/uploads/2022/09/sbom1.png)

How To Automate The Software Bill Of Materials [SBOM] Reflectiz

Unraveling the Mystery

1. MBOM

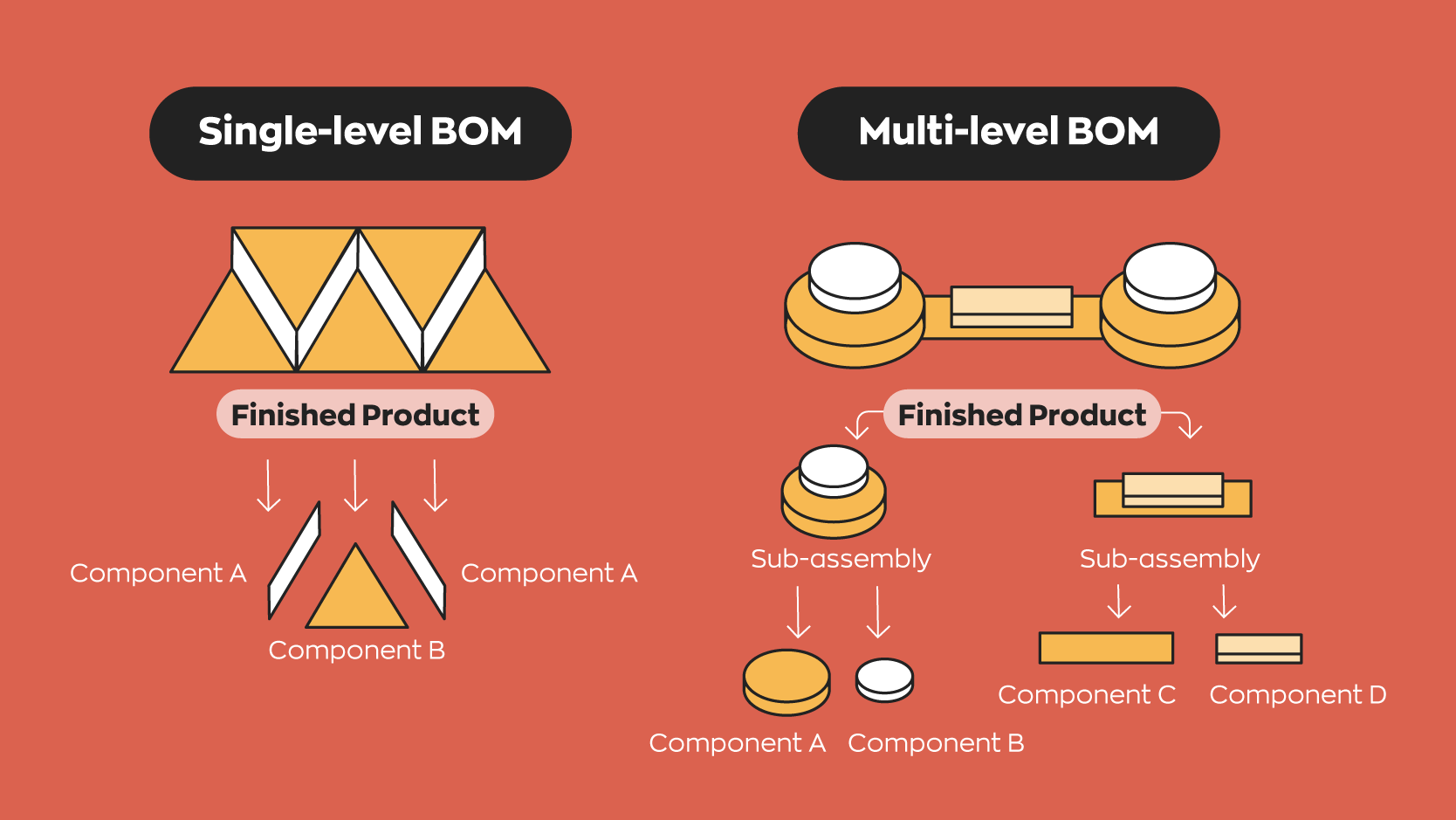

Ever stumbled across the term "MBOM" while navigating the world of SAP and felt a slight sense of bewilderment? You're definitely not alone! MBOM, short for Manufacturing Bill of Material, sounds intimidating, but it's actually a pretty straightforward concept. Think of it as the recipe book for how you build your product, but instead of listing flour and sugar, it lists all the components, assemblies, and instructions needed to create a finished product in the manufacturing process.

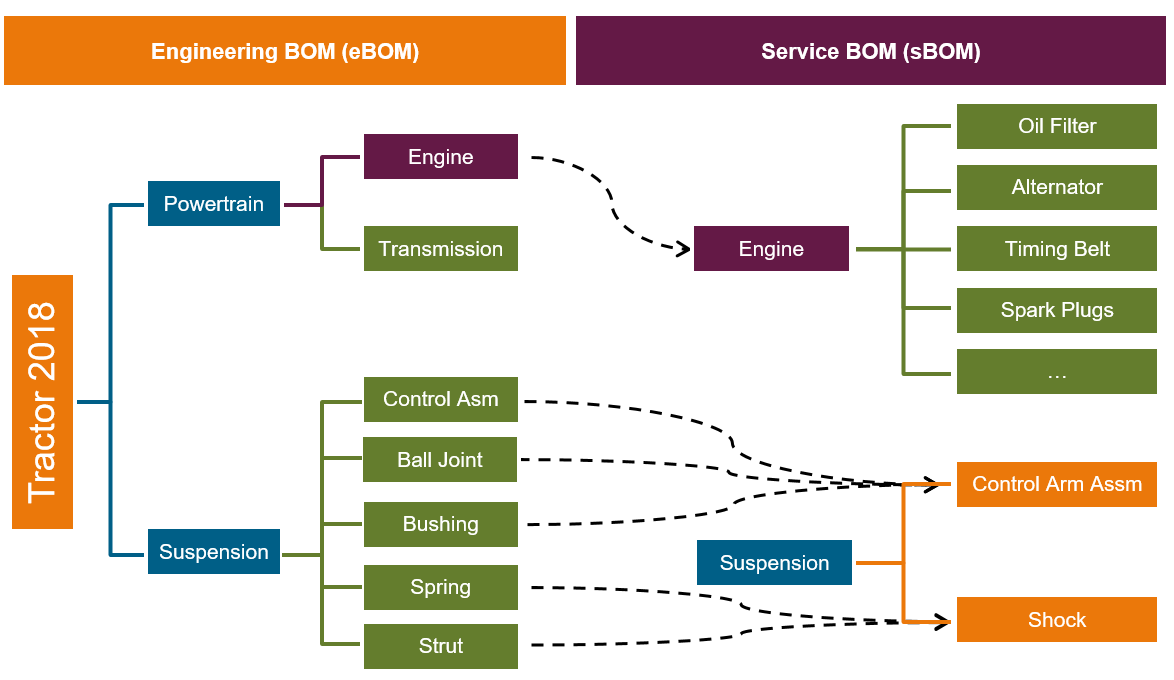

Unlike the Engineering Bill of Material (EBOM), which focuses on the design aspect, the MBOM is all about the "how." It details the specific steps involved in manufacturing, the resources required, and the order in which things need to happen. It's the manufacturer's guide, ensuring that everything comes together smoothly on the shop floor.

Imagine building a car. The EBOM might list the engine, chassis, and interior components. The MBOM, on the other hand, specifies which workstation the engine gets mounted on the chassis, which tools are used, how long each step takes, and even which specific screws are used for each task. Pretty detailed, right? That's the point!

Essentially, the MBOM bridges the gap between design and production. It takes the engineering specifications and translates them into actionable steps for the manufacturing team. Without a well-defined MBOM, you're essentially asking your team to bake a cake without a recipe — you might get something edible, but it probably won't be pretty (or consistent!).

What Is BOM? BOM Types And Formats

Why Should You Care About the MBOM?

2. The Perks of a Solid MBOM

Okay, so you know what an MBOM is, but why should you even care? Well, a well-maintained MBOM can be a game-changer for your manufacturing operations. Think of it as investing in a really good GPS for your factory floor; it keeps everyone on the right track and helps you avoid costly detours.

Firstly, it streamlines production. By having a clear, detailed plan, your team can work more efficiently, reducing bottlenecks and minimizing errors. Secondly, it improves cost control. You know exactly what materials are needed, how much labor is involved, and can accurately track expenses. No more guessing games!

Thirdly, it enhances quality control. With a standardized process, you can ensure that every product is built to the same specifications, reducing defects and improving customer satisfaction. Nobody wants a wonky wheel on their brand new car, and a good MBOM helps avoid such mishaps.

Finally, it supports regulatory compliance. In many industries, manufacturers are required to maintain detailed records of their production processes. A comprehensive MBOM makes it easier to meet these requirements and avoid potential fines or penalties. Think of it as having your homework neatly done and ready to hand in — peace of mind guaranteed!

How To Manage EBOM And MBOM OpenBOM

MBOM vs. EBOM

3. Decoding the BOM Alphabet Soup

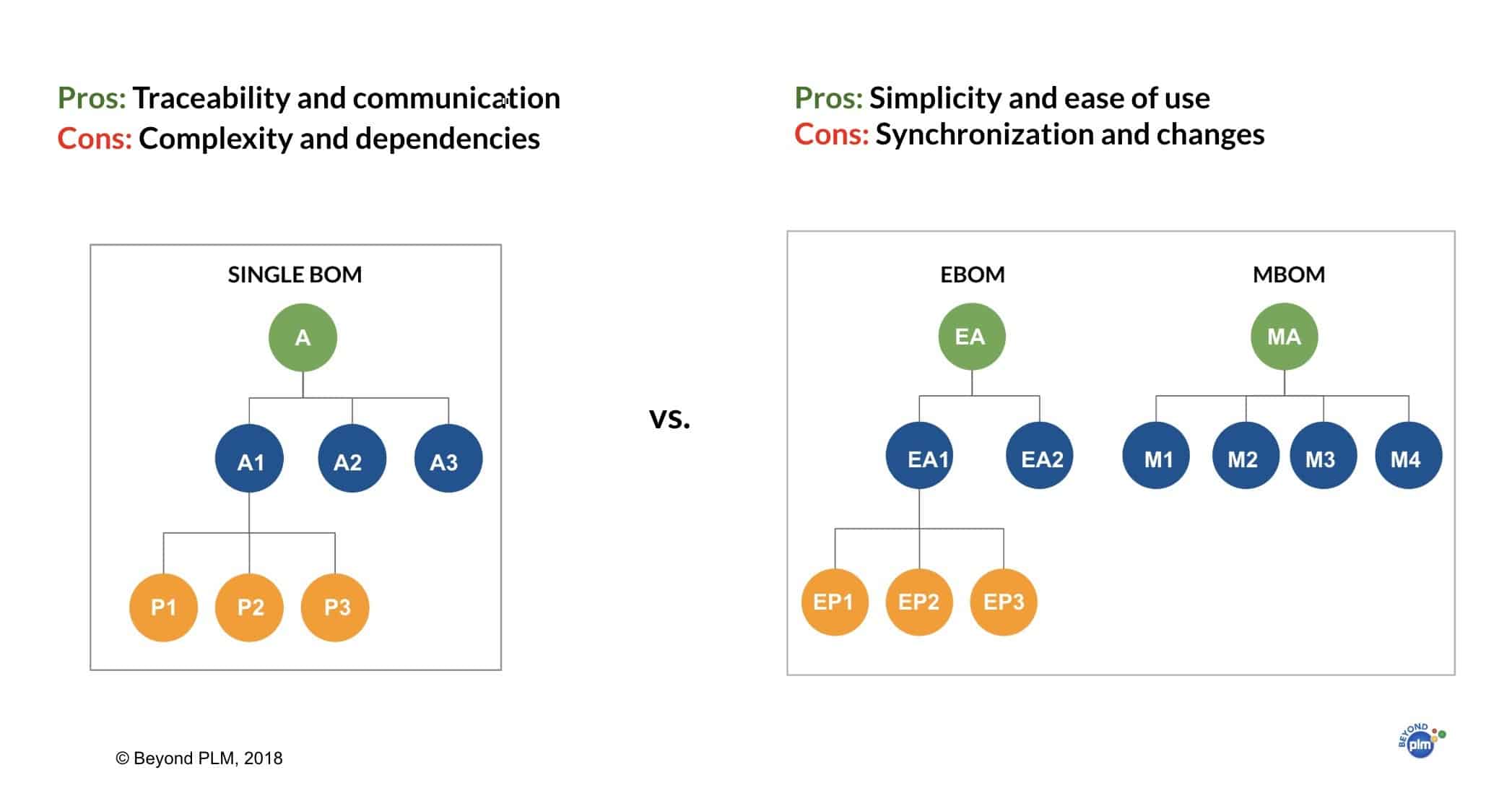

The world of Bills of Material can feel like alphabet soup, with EBOMs, MBOMs, and more floating around. So, how do you keep them straight? The key is understanding their different purposes and the information they contain.

As we touched on earlier, the EBOM (Engineering Bill of Material) is design-focused. It represents the product from an engineering perspective, listing all the parts and components needed for the design, often organized by function or system. It's the blueprint that engineers use to create the product.

The MBOM, on the other hand, is manufacturing-centric. It focuses on the practical steps involved in building the product on the factory floor. It includes information about work centers, tooling, assembly sequences, and other manufacturing-specific details. It's the instruction manual for the production team.

Think of it this way: the EBOM is the architect's plan for a house, while the MBOM is the contractor's guide to actually building it. They're both essential, but they serve different purposes and contain different types of information. Often, a single EBOM can lead to multiple MBOMs, reflecting different manufacturing strategies or plant locations.

MBOM in SAP

4. MBOM's Role in SAP Ecosystem

So, where does MBOM fit into the SAP landscape? SAP offers robust functionalities for managing MBOMs, allowing manufacturers to create, maintain, and use these crucial documents to optimize their production processes. SAP helps integrate MBOM data with other enterprise systems.

Within SAP, the MBOM is typically managed using modules like Production Planning (PP) and Manufacturing Execution System (MES). You can define the MBOM structure, assign components to specific operations, and specify the resources required for each step.

SAP also allows you to link the MBOM to other relevant data, such as work orders, routings, and quality control plans. This integration ensures that all aspects of the manufacturing process are aligned and coordinated, leading to greater efficiency and better quality.

Moreover, SAP provides tools for version control and change management, allowing you to track revisions to the MBOM and ensure that everyone is working with the most up-to-date information. This is particularly important in industries where products are constantly evolving, and changes need to be implemented quickly and accurately. This helps in regulatory compliance in some sector.

Best Practices for MBOM Management

5. Tips and Tricks for MBOM Success

Managing MBOMs effectively can be challenging, but following some best practices can make the process smoother and more rewarding. Think of it as learning the secret handshake to get into the exclusive club of efficient manufacturing.

Firstly, ensure data accuracy and completeness. The MBOM is only as good as the information it contains, so it's crucial to verify that all data is accurate and up-to-date. Regular audits and cross-checks can help identify and correct any errors. Garbage in, garbage out, as they say!

Secondly, establish clear roles and responsibilities. Define who is responsible for creating, maintaining, and approving changes to the MBOM. This ensures that everyone knows their role and accountability is clear. This reduces risk of errors.

Thirdly, integrate the MBOM with other enterprise systems. Linking the MBOM to your ERP, MES, and other systems allows for seamless data flow and better visibility across the entire manufacturing process. This integration allows for real time adjustments.

Finally, provide adequate training to your team. Ensure that everyone who uses the MBOM understands its purpose and how to use it effectively. Training can help reduce errors and improve overall efficiency. Remember, a well-trained team is a happy team (and a productive one!).

Frequently Asked Questions (FAQs)

6. Your MBOM Questions Answered

Q: What's the difference between a BOM and an MBOM?A: A BOM (Bill of Material) is a general term, while an MBOM (Manufacturing Bill of Material) is a specific type of BOM that focuses on the manufacturing process. The MBOM includes details about how a product is built, not just what parts are needed.

Q: Can an EBOM be converted into an MBOM?A: Yes, an EBOM can serve as the foundation for an MBOM. However, the EBOM needs to be augmented with manufacturing-specific details, such as work centers, tooling, and assembly sequences, to create a complete MBOM.

Q: How often should an MBOM be updated?A: An MBOM should be updated whenever there are changes to the manufacturing process, such as new equipment, revised routings, or updated component specifications. Regular reviews and updates are crucial for maintaining accuracy and efficiency.

Q: What are the key benefits of using MBOM in SAP?A: Streamlined production, improved cost control, enhanced quality control, better compliance, and real-time visibility into the manufacturing process.