First Class Info About What Are The 4 Types Of SIL

Types Of Soil Science Facts

Decoding SIL

Ever heard someone talking about SIL and thought, "Is that a typo for 'sill'?". Well, probably not if you're reading this! SIL stands for Safety Integrity Level, and it's a big deal in industries where safety is paramount. Think oil and gas, nuclear power, or even your local water treatment plant. Its basically a way of measuring the level of risk reduction provided by a safety function. Let's dive into what it means, why it matters, and most importantly, what are the 4 types of SIL.

But before we get to the juicy details, let's understand the basic idea. Imagine a factory with a potentially dangerous machine. Now, imagine adding layers of safety mechanisms to prevent accidents. SIL helps quantify how much each layer contributes to making the workplace safer. Its a structured way to make sure everything is done according to best practices and standards.

Think of it like this: SIL is to safety what calorie counting is to dieting. It's a system that helps you achieve your goal (in this case, a safe environment) by quantifying and managing all the contributing factors. And just like calorie counting, it can seem a bit daunting at first, but trust me, once you grasp the basics, it all clicks into place.

So, grab your metaphorical hard hat, and lets explore the world of Safety Integrity Levels. Prepare to be amazed (or at least mildly interested)! We're about to peel back the layers of complexity and uncover the core of this fascinating subject. And yes, we will definitely get to those four types! Consider this your friendly guide to navigating the sometimes-confusing world of industrial safety.

What Exactly Is a Safety Integrity Level?

1. The Heart of the Matter

At its core, a Safety Integrity Level (SIL) is a relative level of risk reduction provided by a safety function. Thats the official definition, anyway. In simpler terms, its a way to measure how well a safety system is doing its job. It tells you how likely the system is to prevent a dangerous situation from occurring.

Imagine a pressure cooker. A SIL-rated pressure cooker would have multiple safety mechanisms — maybe a pressure relief valve, a locking lid, and temperature sensors. The SIL rating would tell you how reliable these systems are in preventing an explosion (a very undesirable outcome!).

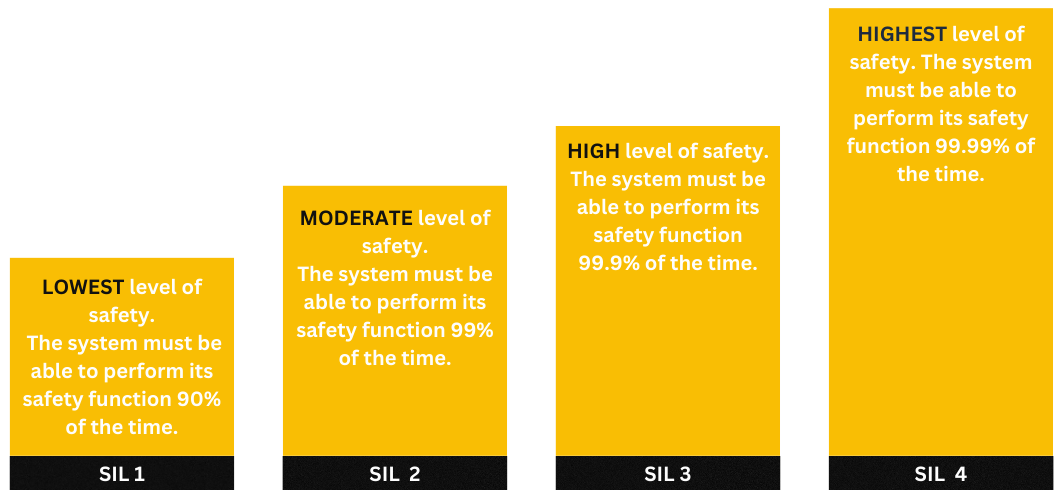

The higher the SIL, the lower the probability of a dangerous failure. SILs range from 1 to 4, with 4 offering the highest level of safety and risk reduction. Achieving a higher SIL often means more sophisticated (and sometimes more expensive) safety systems.

It's important to note that SIL is not about eliminating risk entirely. It's about reducing it to a tolerable level. No system is 100% foolproof, but with proper SIL implementation, you can significantly minimize the chances of something going wrong. It's all about creating a safe and reliable environment for everyone involved.

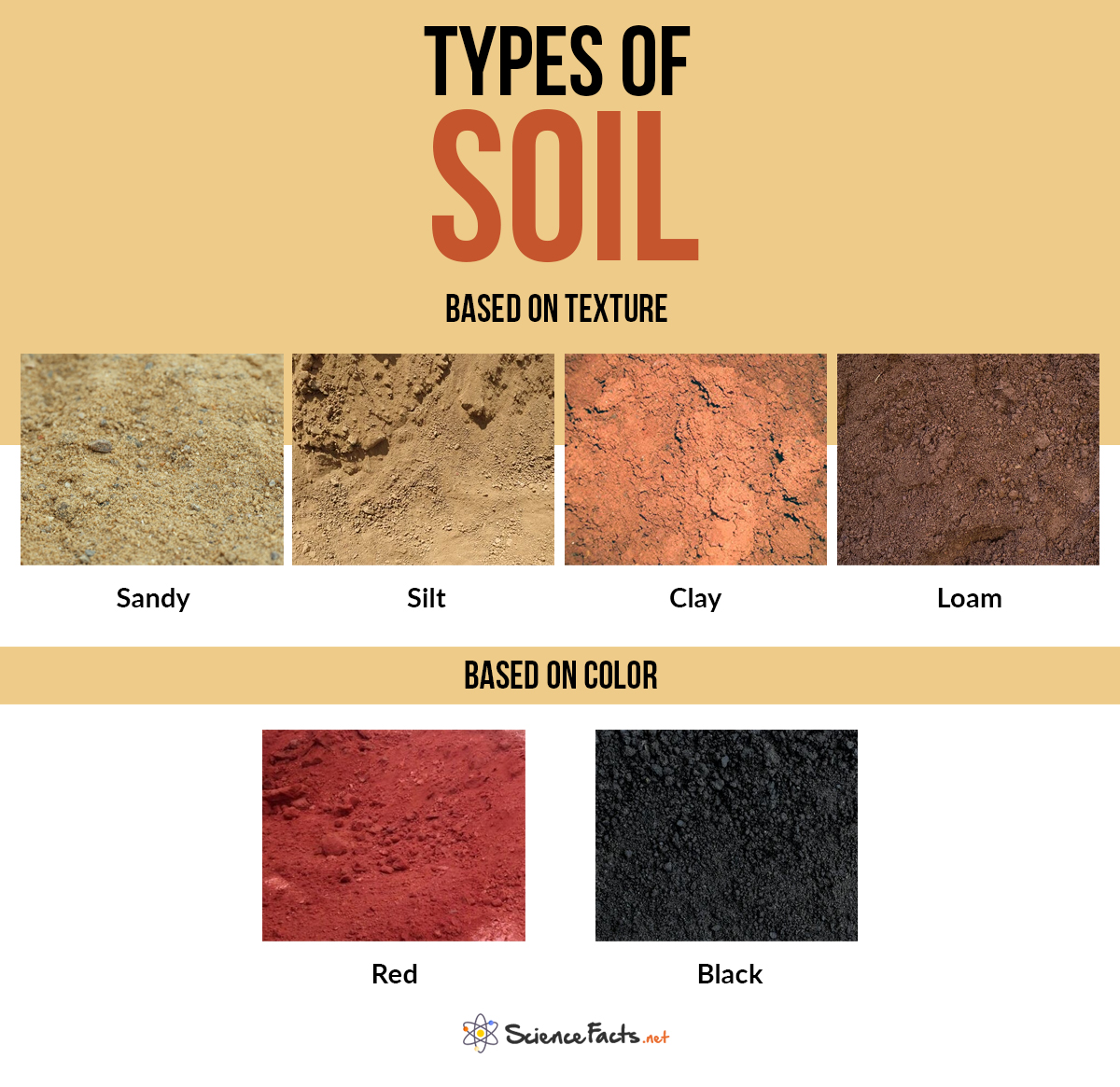

Types Of Soil With Pictures

Okay, Here Are The 4 Types of SIL

2. Breaking Down the Levels

Alright, let's get down to business! Here are the four Safety Integrity Levels, each with its own characteristics and requirements:

SIL 1: The Foundation of Safety

SIL 1 represents the lowest level of safety integrity. Safety functions at this level provide a basic level of risk reduction. It's often applied to relatively simple safety systems where the consequences of failure are not catastrophic, but still undesirable.

Think of a simple light curtain protecting a machine operator's hand. If the hand breaks the light beam, the machine stops. This might be a SIL 1 application. It provides a definite level of protection but doesnt involve highly complex technology or redundant systems.

Typically, achieving SIL 1 involves well-designed systems, proper maintenance, and adherence to industry best practices. The emphasis is on preventing common and reasonably foreseeable hazards.

While it's the lowest SIL, its crucial. Its the foundation upon which more complex safety systems are built. Don't underestimate the importance of a good SIL 1 implementation!

SIL 2: Stepping Up the Protection

SIL 2 indicates a higher level of risk reduction than SIL 1. Safety functions at this level are implemented to address more significant hazards with potentially more severe consequences. Systems designed for SIL 2 often incorporate more sophisticated technology and redundancy.

Imagine a chemical plant with a tank that needs to be prevented from overfilling. A SIL 2 system might involve multiple level sensors, independent shut-off valves, and an alarm system to alert operators to a potential problem. The redundancy ensures that even if one component fails, the system will still function.

Achieving SIL 2 requires a more rigorous design process, including detailed hazard analysis, failure mode and effects analysis (FMEA), and careful selection of components. Testing and validation are also crucial to ensure the system performs as expected.

SIL 2 is often a sweet spot for many industrial applications, providing a balance between cost and risk reduction. It represents a significant step up in safety compared to SIL 1.

SIL 3: Serious Safety Measures

SIL 3 represents a substantial level of risk reduction and is applied to systems where the consequences of failure could be severe, potentially involving significant injury, environmental damage, or financial loss. Systems designed for SIL 3 require a high degree of reliability and availability.

Consider an emergency shutdown system (ESD) in an offshore oil platform. This system is designed to automatically shut down critical processes in the event of a fire, explosion, or other dangerous situation. A SIL 3 rated ESD would have multiple layers of redundancy, sophisticated diagnostics, and rigorous testing procedures.

Achieving SIL 3 requires meticulous design, extensive testing, and independent validation. The components used must be highly reliable, and the system must be designed to tolerate faults. Regular maintenance and proof testing are essential to maintain the required level of safety integrity.

SIL 3 is often used in industries with high-risk processes where the potential for catastrophic events is a real concern. It represents a significant investment in safety, but one that is often justified by the potential consequences of failure.

SIL 4: The Highest Level of Safety

SIL 4 represents the highest level of safety integrity and is reserved for systems where the consequences of failure could be catastrophic, potentially involving multiple fatalities or irreversible environmental damage. Systems designed for SIL 4 require an extremely high degree of reliability and availability.

An example of a SIL 4 application might be the safety system in a nuclear power plant designed to prevent a reactor meltdown. Such a system would have multiple independent and redundant safety functions, each designed to prevent or mitigate the consequences of a nuclear accident. The design and implementation of such systems are subject to intense scrutiny and regulatory oversight.

Achieving SIL 4 is extremely challenging and requires specialized expertise, rigorous design processes, and extensive testing and validation. The components used must be of the highest quality and reliability, and the system must be designed to tolerate multiple faults. Regular maintenance, proof testing, and independent audits are essential to maintain the required level of safety integrity.

SIL 4 is rarely used outside of a small number of very high-risk industries. It represents the ultimate commitment to safety and risk reduction, but comes at a significant cost and complexity.

Why Does Any of This Matter?

3. The Importance of SIL in the Real World

You might be thinking, "Okay, that's a lot of technical jargon. Why should I care about SIL?". Well, the answer is simple: SIL saves lives and protects the environment. It helps prevent accidents that could have devastating consequences.

Imagine a world without SIL. Factories would be more dangerous, chemical plants would be more prone to explosions, and nuclear power plants would be a lot riskier. SIL provides a framework for ensuring that safety systems are designed and implemented to the highest standards.

Beyond the ethical considerations, SIL also makes good business sense. Accidents can lead to costly downtime, damage to equipment, and legal liabilities. By investing in SIL, companies can reduce their risk exposure and improve their bottom line.

Furthermore, regulatory bodies often require companies to implement SIL in high-risk industries. Compliance with these regulations is not only a legal requirement but also a matter of maintaining a good reputation and avoiding penalties.

So, whether you're an engineer, a manager, or simply a concerned citizen, understanding SIL is important. It's a critical component of ensuring a safe and sustainable future. It's a proactive approach to identifying and mitigating risks before they lead to accidents.

Frequently Asked Questions (FAQs) About SIL

4. Your Burning Questions Answered

Here are some common questions about SIL that might be swirling around in your head right now:

Q: How do I determine the appropriate SIL for my application?

A: Determining the appropriate SIL requires a thorough hazard analysis and risk assessment. This involves identifying potential hazards, evaluating the likelihood and severity of their consequences, and then selecting a SIL that provides an adequate level of risk reduction. Consulting with experienced safety engineers is highly recommended.

Q: What are the different standards for SIL?

A: The most common standards for SIL are IEC 61508 and IEC 61511. IEC 61508 is a generic standard for functional safety, while IEC 61511 is specific to the process industry. Other industry-specific standards may also apply.

Q: Is SIL certification required?

A: While not always mandatory, SIL certification can provide assurance that a safety system meets the required standards and provides the intended level of risk reduction. It's often required by regulatory bodies or customers in high-risk industries. The need for certification depends on the specific application and regulatory requirements.

Types Of Soil HandsOn Activity