Smart Info About What Is The Purpose Of A Torque Meter

Decoding the Torque Meter

1. Understanding the Basics

Ever wondered how mechanics tighten bolts with such precision? Or how engineers ensure the safety of a skyscraper's structure? The secret weapon in their arsenal is often a torque meter. In essence, a torque meter (noun) is an instrument designed to measure torque, which, simply put, is a twisting force. Think of it as the rotational equivalent of linear force. It tells you exactly how much "oomph" you're applying when tightening a screw or rotating a shaft.

But why bother measuring torque in the first place? Well, imagine tightening the lug nuts on your car tires. Too loose, and your wheel could come flying off (yikes!). Too tight, and you risk stripping the threads or warping the rotor. A torque meter helps you hit that "Goldilocks" zone — just right. It's all about precision and safety. Torque is a crucial factor in various mechanical applications, and measuring it accurately is vital for ensuring proper functionality, preventing failures, and maintaining safety standards.

Think of a torque meter as the unsung hero of countless industries. From automotive manufacturing to aerospace engineering, it plays a crucial role in ensuring that everything is assembled correctly and functions as intended. Without it, we'd be relying on guesswork, which, let's face it, isn't the most reliable method when dealing with complex machinery or critical structures. Now, isn't that a comforting thought knowing this is more than just twisting things?

Essentially, it bridges the gap between "tight enough" and "catastrophically overtightened," offering a precise measurement that eliminates the guesswork. A torque meter isn't just a tool; it's a safeguard against potential disasters, a guarantor of quality, and a testament to the importance of precision in the mechanical world. The applications are surprisingly broad and impact nearly every aspect of modern engineering and manufacturing.

Torque Meter Mechanism At Helen Parnell Blog

Why Precise Torque Matters

2. The Importance of Accuracy

So, we know a torque meter measures twisting force. But why is that measurement so important? Well, imagine you're building a model airplane. If you overtighten the screws holding the wings on, you might crack the plastic. Undortighten them, and the wings might fall off mid-flight (not ideal!). In many engineering and manufacturing scenarios, the consequences of incorrect torque can be much more serious. Were talking about potential equipment failure, safety hazards, and even catastrophic accidents. The keyword torque meter helps avoiding such scenario.

Consider the assembly of an engine. Each bolt needs to be tightened to a specific torque to ensure proper sealing and prevent leaks. Too much torque can damage the threads or distort the components, while too little torque can lead to vibrations and eventual failure. This isn't just about making sure things are "stuck together;" it's about ensuring that everything functions harmoniously under pressure and stress. The precise application of torque is an art and a science, and a torque meter is the brush and palette that allows engineers and technicians to master this discipline.

Think about bridges, buildings, and airplanes. These structures rely on thousands of precisely tightened fasteners to maintain their structural integrity. A single incorrectly torqued bolt could compromise the entire system. The torque meter, therefore, becomes an indispensable tool for ensuring safety and reliability in critical applications. It provides the data necessary to verify that fasteners are tightened according to specifications, preventing costly mistakes and potential disasters. This accuracy can save lives, prevent property damage, and ensure the long-term performance of critical infrastructure.

Moreover, precise torque control is increasingly important in the age of advanced materials and complex designs. Modern vehicles, for example, incorporate lightweight alloys and intricate assemblies that are highly sensitive to torque. A torque meter ensures that these components are not overstressed or damaged during assembly, maintaining the vehicle's performance and lifespan. So, next time you see a mechanic using a torque wrench, remember that they're not just tightening a bolt; they're ensuring the reliability and safety of your vehicle.

Types of Torque Meters

3. Exploring the Options

Torque meters come in various shapes and sizes, each designed for specific applications. The simplest type is the click-type torque wrench, which is often used by mechanics and DIY enthusiasts. These wrenches allow you to set a desired torque value, and they "click" when that value is reached, preventing you from overtightening the fastener. They are durable, reliable, and relatively affordable, making them a popular choice for general-purpose applications. The simple click provides tactile and audible confirmation that the desired torque has been achieved. It's a user-friendly tool that helps prevent over-tightening and ensures consistent results.

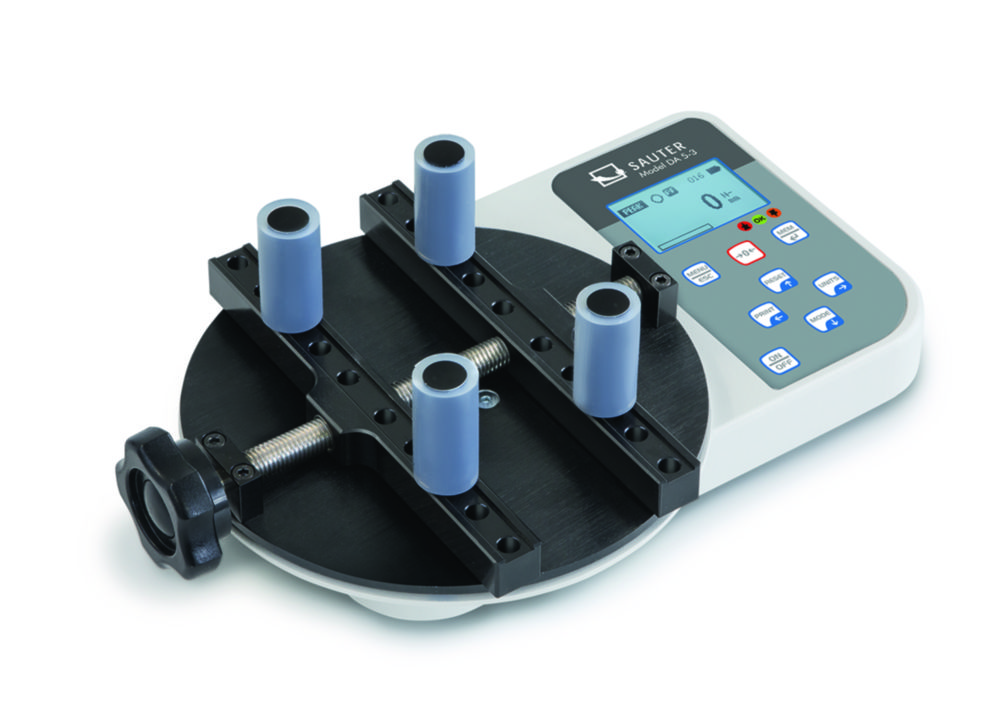

Then there are digital torque meters, which provide a numerical readout of the applied torque. These meters are more accurate than click-type wrenches and are often used in applications where precise torque control is critical. Digital torque meters often come with features like data logging and wireless connectivity, allowing you to track and analyze torque measurements over time. They offer unparalleled precision and are invaluable in research, development, and quality control applications.

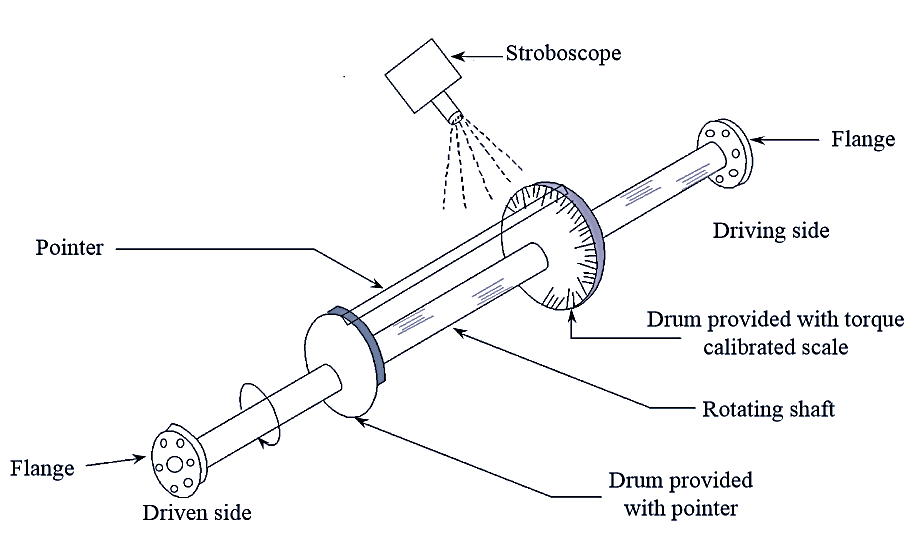

For more specialized applications, there are rotary torque sensors, which are used to measure the torque of rotating shafts. These sensors are often found in engine test stands and dynamometers, where they are used to measure the power output of engines and motors. Rotary torque sensors utilize strain gauges or other advanced sensing technologies to accurately measure the twisting force on a rotating shaft. They are essential for optimizing engine performance, validating designs, and ensuring the reliability of rotating equipment.

Finally, there are hydraulic torque wrenches, which are used for tightening very large fasteners, such as those found in bridges and pipelines. These wrenches use hydraulic pressure to generate enormous amounts of torque. They are typically used in heavy-duty applications where manual tightening is impossible. Each torque meter types offers unique advantages depending on the task at hand. The choice of torque meter depends on the specific application, the desired level of accuracy, and the budget. Understanding the different types of torque meters is essential for selecting the right tool for the job.

What Is Torque In Energy Meter At Grady Naylor Blog

Applications Across Industries

4. From Automotive to Aerospace

The applications of torque meters are incredibly diverse, spanning across numerous industries. In the automotive industry, they're used to tighten everything from engine components to wheel nuts, ensuring the reliability and safety of vehicles. Mechanics rely on them to accurately torque head bolts, crankshaft bolts, and other critical fasteners. The automotive industry is a major consumer of torque meters, with a wide range of applications from manufacturing to repair.

In the aerospace industry, torque meters are used to assemble aircraft engines, landing gear, and other critical components. The stakes are exceptionally high, and any error in torque application could have catastrophic consequences. The aerospace sector demands the highest levels of precision and reliability, making torque meters indispensable tools for ensuring the safety of aircraft. Strict regulations and quality control standards further emphasize the importance of precise torque control in aerospace manufacturing and maintenance.

Construction also relies heavily on torque meters for the assembly of bridges, buildings, and other structures. Ensuring that bolts are tightened to the correct torque is essential for maintaining the structural integrity of these massive constructions. Construction engineers and workers use torque wrenches to tighten structural bolts, foundation bolts, and other critical fasteners. The longevity and safety of buildings and infrastructure depend on the accurate application of torque, making torque meters an essential tool for construction professionals.

Beyond these major industries, torque meters are also used in manufacturing, research and development, and quality control. They're employed in the production of medical devices, electronics, and countless other products where precise torque control is essential. Torque meters help manufacturers ensure consistency, improve product performance, and reduce the risk of failures. Whether it's tightening screws in a smartphone or assembling a satellite, torque meters play a vital role in ensuring the quality and reliability of modern products. Remember, the torque meter impacts our safety in all aspects.

Range Of Torque Meter At AdvanceTech

Choosing the Right Torque Meter

5. Factors to Consider

Selecting the appropriate torque meter can seem daunting, but it boils down to understanding your specific needs. First, consider the torque range you'll be working with. Will you be tightening small screws or large bolts? Ensure that the torque meter you choose covers the necessary range. Overextending the meter's capabilities can lead to inaccurate readings and potential damage to the tool. Choosing the right torque range is crucial for achieving accurate and reliable measurements.

Next, think about the accuracy you require. For critical applications, a digital torque meter with a high degree of accuracy is essential. For less demanding tasks, a click-type torque wrench might suffice. Higher accuracy usually comes with a higher price tag, so it's important to balance your needs with your budget. Consider the manufacturer's specifications and calibration standards to ensure the torque meter meets your accuracy requirements.

Also, consider the environment in which you'll be using the torque meter. Will it be exposed to harsh conditions, such as dirt, moisture, or extreme temperatures? If so, choose a rugged and durable model. Select a torque meter that is designed to withstand the environmental conditions of your workplace. Consider features such as water resistance, impact resistance, and corrosion resistance to ensure the tool's longevity and reliability.

Finally, don't forget about ergonomics. A comfortable and easy-to-use torque meter will reduce fatigue and improve efficiency. Look for features such as a comfortable grip, a clear display, and intuitive controls. A well-designed torque meter can significantly improve your workflow and reduce the risk of errors. Consider the tool's weight, balance, and ease of handling to ensure it is comfortable to use for extended periods. The best torque meter is the one that meets all needs and is user friendly.